The Allure of Crafting Your Own Farmhouse Table

Picture this: A bustling family gathering, the aroma of a home-cooked meal wafting through the air, laughter echoing, and at the heart of it all, a stunning wooden farmhouse table. Not just any table, but one you crafted with your own hands. In a world dominated by factory-produced furniture, the charm and warmth of a DIY wooden table stand unparalleled.

The Craftsmanship Behind the Farmhouse Table

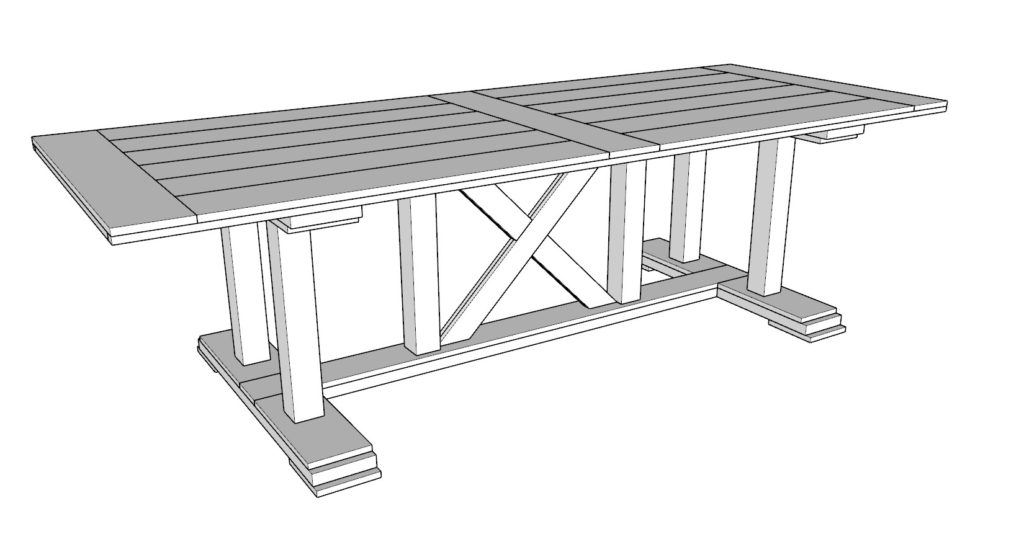

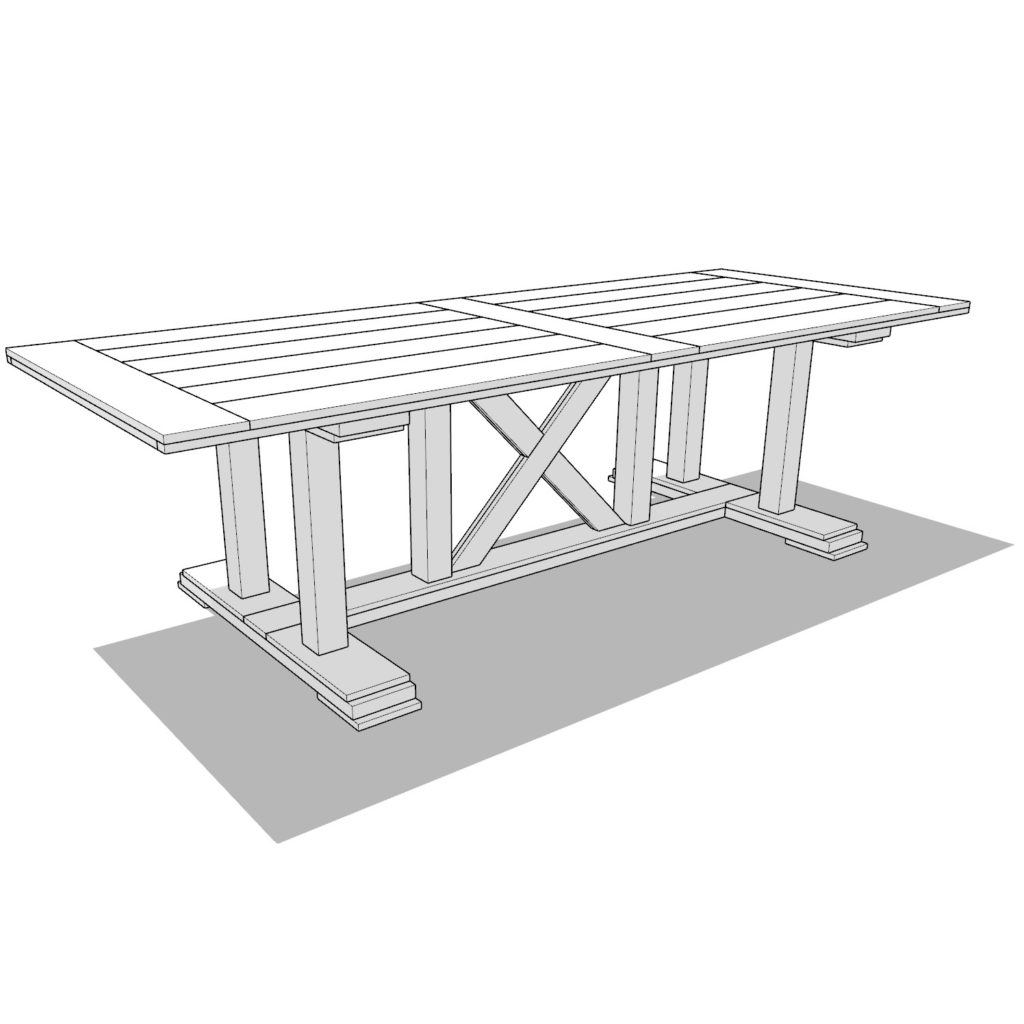

Diving into the art of DIY, especially when it’s about creating a centerpiece for your home, is a journey filled with excitement and pride. This farmhouse table, made entirely of wood, boasts a signature crossbuck design that’s not only visually appealing but ensures stability. And for those concerned about the logistics of moving such a sizable piece, fret not! Its detachable top is a testament to thoughtful design, allowing ease of relocation without compromising on aesthetics.

Elevate Your Dining Space

The farmhouse table is more than just a functional piece; it’s a style statement. To elevate its rustic charm, consider pairing it with wooden chairs, particularly those with an ‘X’ backrest. This combination, tried and tested in numerous setups, exudes an aura of rustic sophistication, making every meal feel like a special occasion.

A Table for Every Gathering

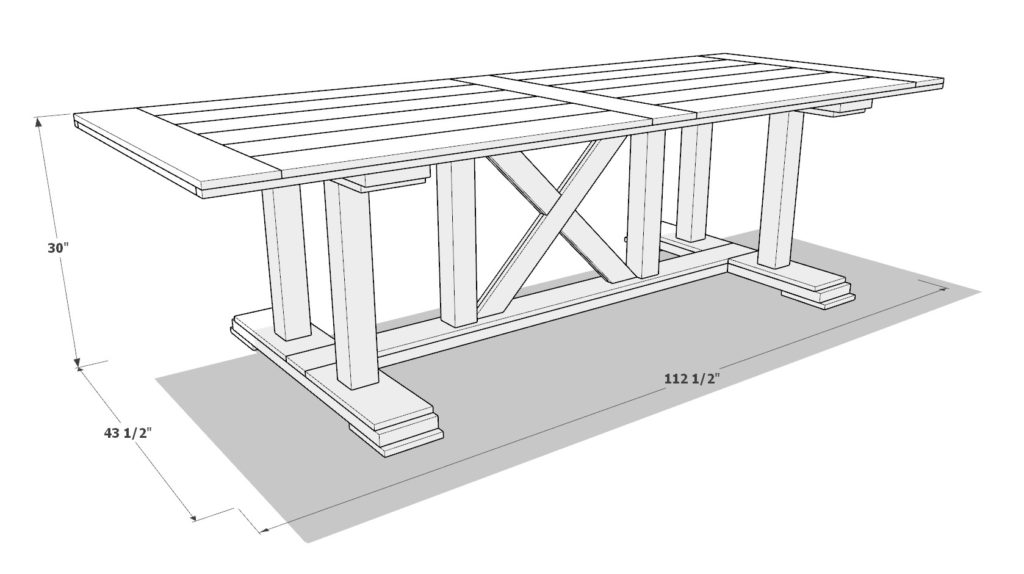

Stretching to a generous 112-1/2 inches, this table isn’t just about aesthetics; it’s about bringing people together. It comfortably accommodates ten, ensuring that no one’s left standing during those festive dinners or spontaneous get-togethers.

DIY: The Perfect Blend of Savings and Satisfaction

Why splurge on an exorbitantly priced store-bought table when you can craft a personalized masterpiece at a fraction of the cost? Beyond the evident monetary savings, the DIY route offers something priceless: the joy of creation. Every groove, every joint, becomes a cherished memory of the time and effort you invested.

Crafting Simplified with Our Guide

For many, the realm of DIY may seem a tad overwhelming. But our comprehensive guide is here to change that perception. Tailored especially for novices, our plan covers every nuance, from construction to finishing touches. Whether you’re pondering over the perfect stain, figuring out distressing techniques, or seeking tips to cover up those pesky nail holes, our guide has you covered.

Join the DIY Revolution

The joy of dining on a table you’ve crafted is unmatched. It’s not just about the tangible result but the memories embedded in each plank and nail. Our detailed plan is your passport to this fulfilling journey. Ready to roll up your sleeves and create a masterpiece? Secure your guide now and embark on an unforgettable DIY adventure.

Time

12 hours

Cost

$400

Skill level required

Beginner

DIY Farmhouse Table PDF plan

What is included in the PDF download?

- Easy to read step by step instructions

- Material list

- Tools needed

- Helpful links to materials and tools needed

DIY Farmhouse Table Dimensions

Tools Needed for This Project:

Available with the purchase of the DIY plan PDF. Thank you for your support and for making this site possible.

Lumber Shopping & Cut List

Available with the purchase of the DIY plan PDF. Thank you for your support and for making this site possible.

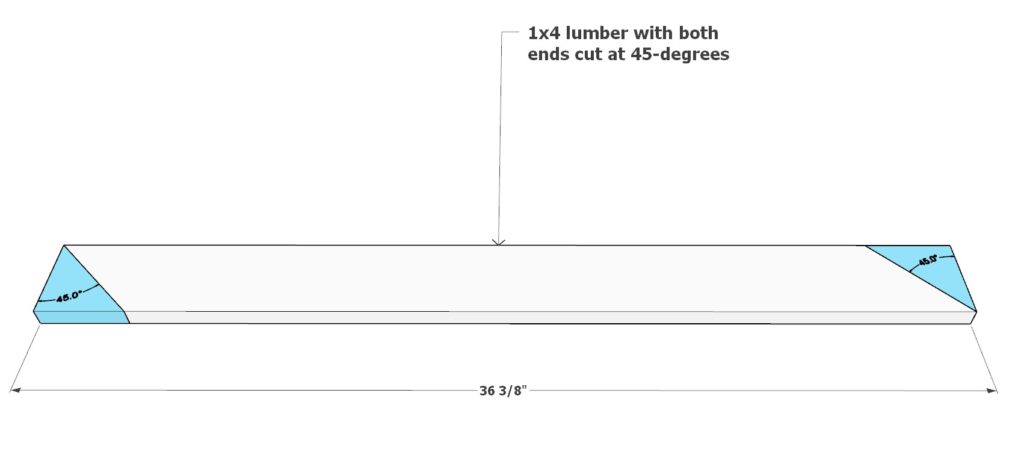

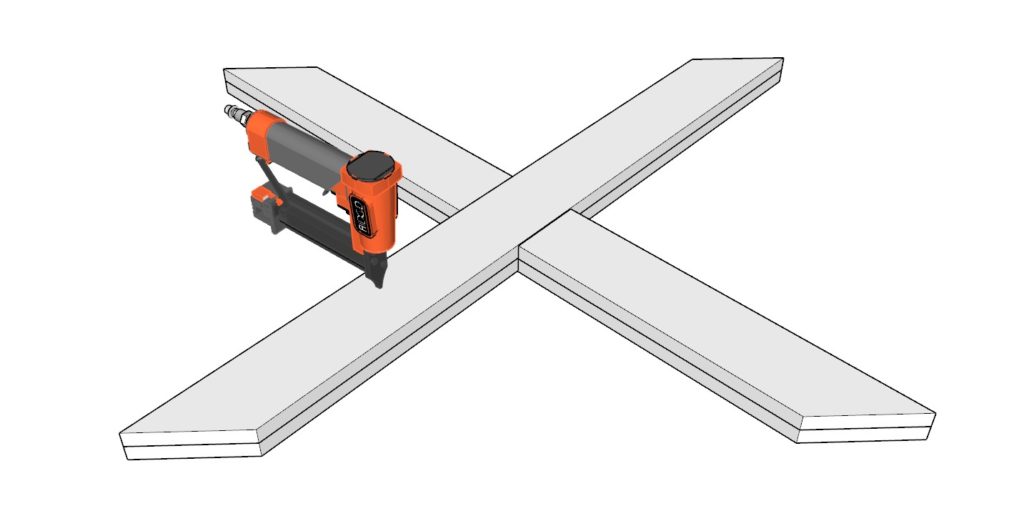

Step 1: Constructing the Crossbuck Base

Begin the table’s foundation by crafting its distinctive crossbuck (or trestle) base.

Preparation of Lumber:

- Before starting with the cuts, pass each board through a planer. This ensures they’re straight, even, and reduces sanding time later.

- For an enhanced finish, sand each board lightly after planing.

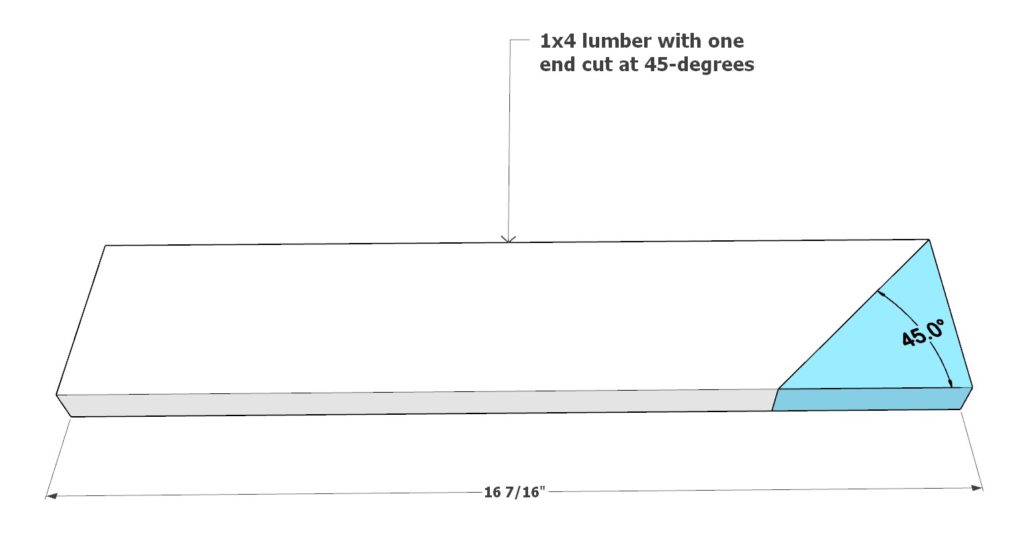

Cutting the Lumber:

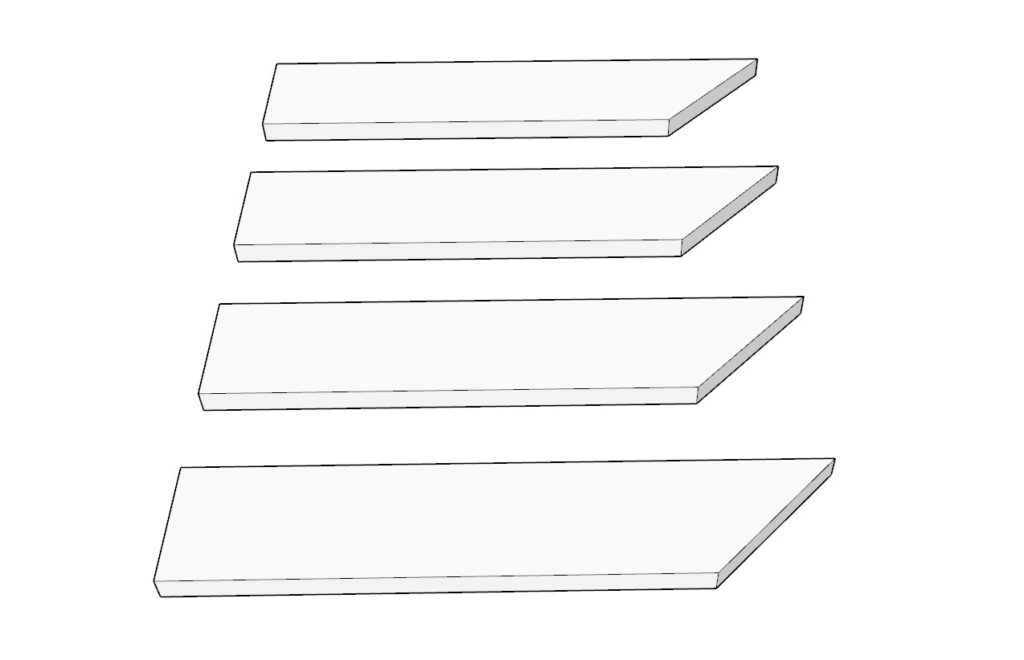

- Start with a 36-3/8 inch long 1×4 lumber piece. Angle your saw to 45-degrees and trim both ends as indicated in the provided diagram. Repeat to get a total of two pieces.

- For the shorter pieces, take a 16-7/16 inch long 1×4 lumber and similarly cut one end at a 45-degree angle. Ensure you have four of these pieces in total.

Assembly:

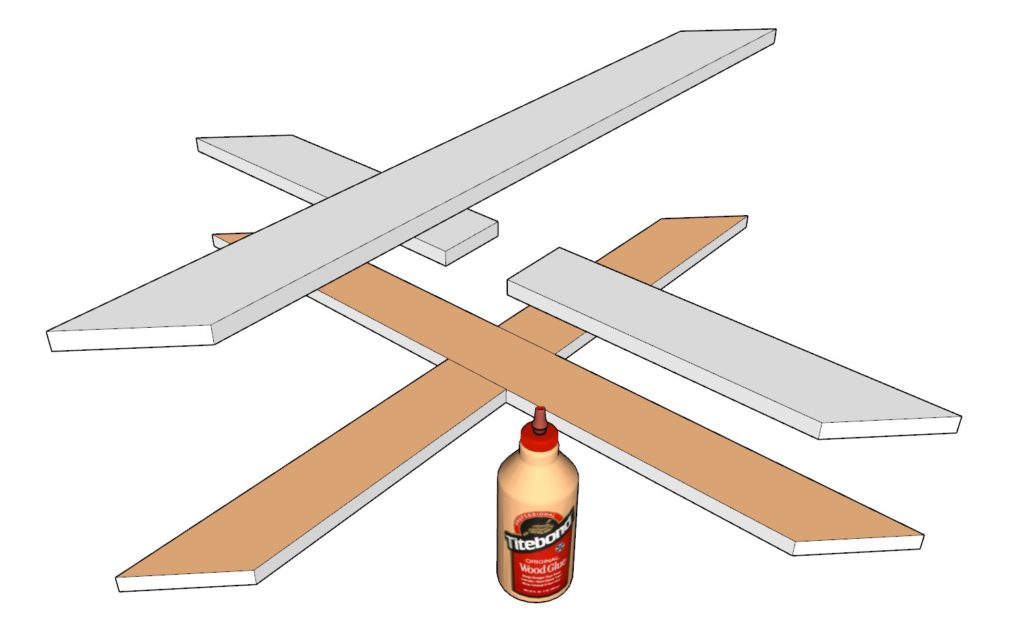

- Lay out the cut components as illustrated in the diagram below.

- Apply a generous amount of wood glue at the joints to ensure a strong bond.

- Using a nail gun, secure the pieces together with 1-inch nails.

Pro Tip: For a seamless look, always make sure to wipe away any excess glue immediately after joining two pieces. This prevents hardened glue spots which can disrupt the finishing process later on.

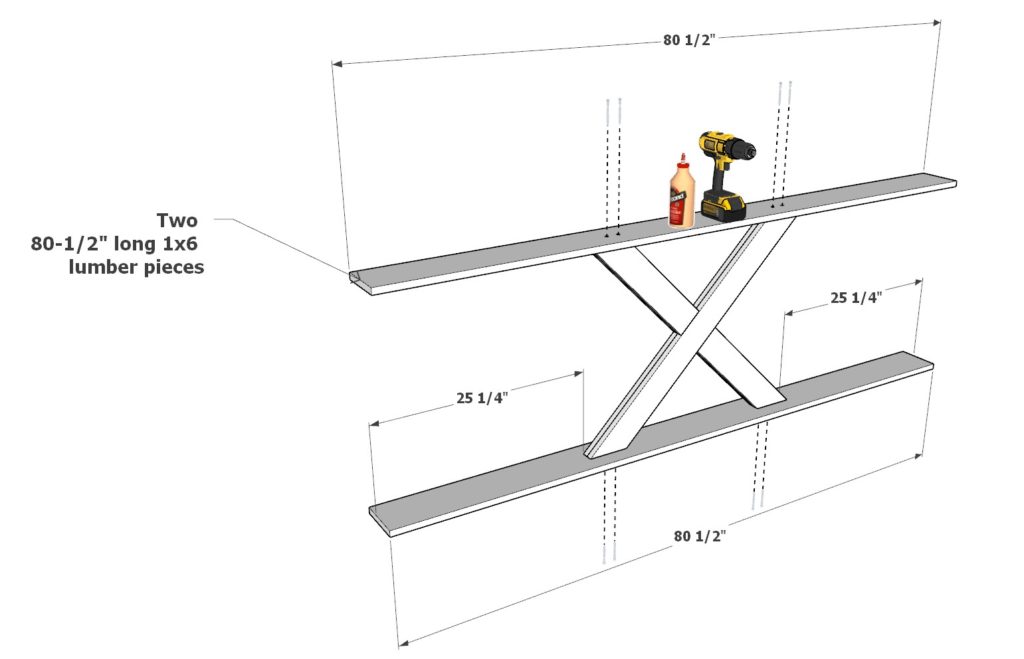

Step 2: Adding the Stretcher and Central Planks

Strengthen and unify your table’s base by attaching the central beam, also known as the stretcher, followed by the central planks.

Attaching the Stretcher:

- Obtain two 80-1/2″ long 1×6 lumber pieces.

- Align them to the crossbuck base as depicted in the diagram below.

- Before joining, apply wood glue thoroughly to all contact areas.

- For a solid connection, predrill holes and then secure the pieces using 3-inch screws.

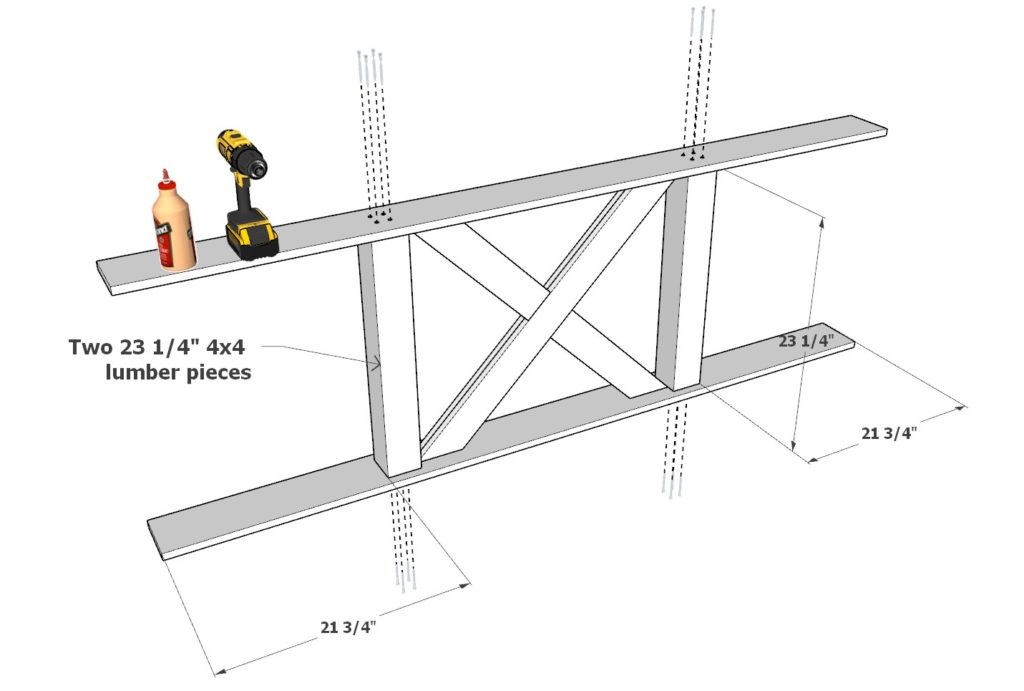

- Add two 23-1/4″ 4×4 lumber boards next to the crossbuck and secure them in place using 3-inch screws

Pro Tip: Always predrill holes, especially near the ends of boards, to prevent the wood from splitting.

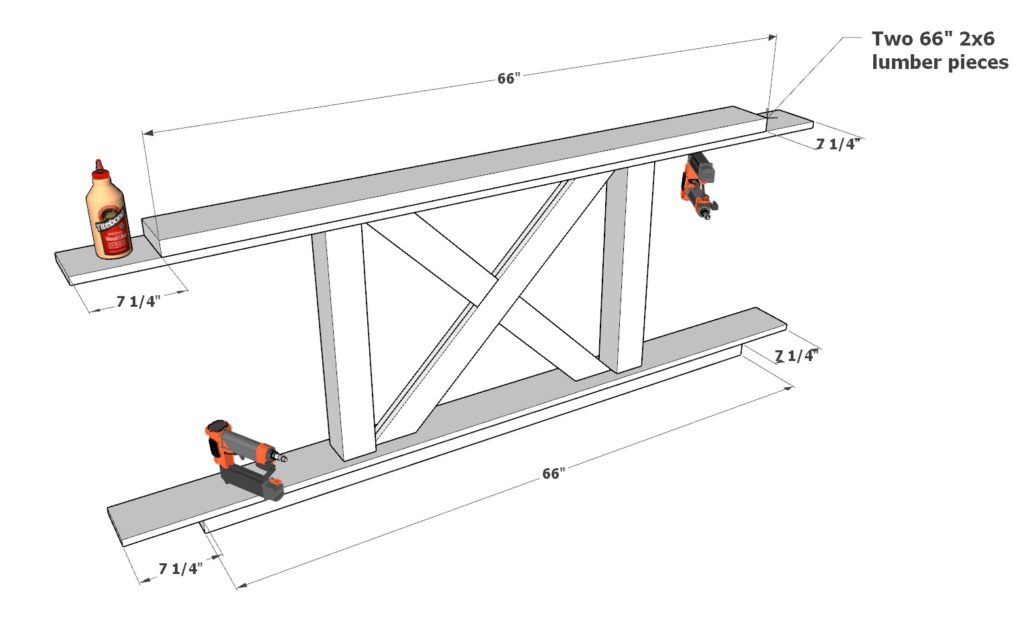

- Take two 66-inch 2×6 lumber pieces.

- Position them on top of the 80-1/2″ 1×6 lumber pieces, ensuring they are centered.

- Apply wood glue at the joints for a sturdy bond.

Use a nail gun to fasten the planks in place with 1-inch nails.

Mounting the Central Planks:

Pro Tip: For a refined appearance, sand each component after assembly, ensuring smooth transitions between joined pieces.

Step 3: Crafting and Assembling the Table Legs

Establish a strong foundation for your table by creating robust table legs and seamlessly integrating them with the stretcher.

Pro Tip: When working with wood, tools like planers, saws, and extensive sanding can introduce slight variations in measurements. Before proceeding, double-check that a 25-inch long 4×4 matches your needs.

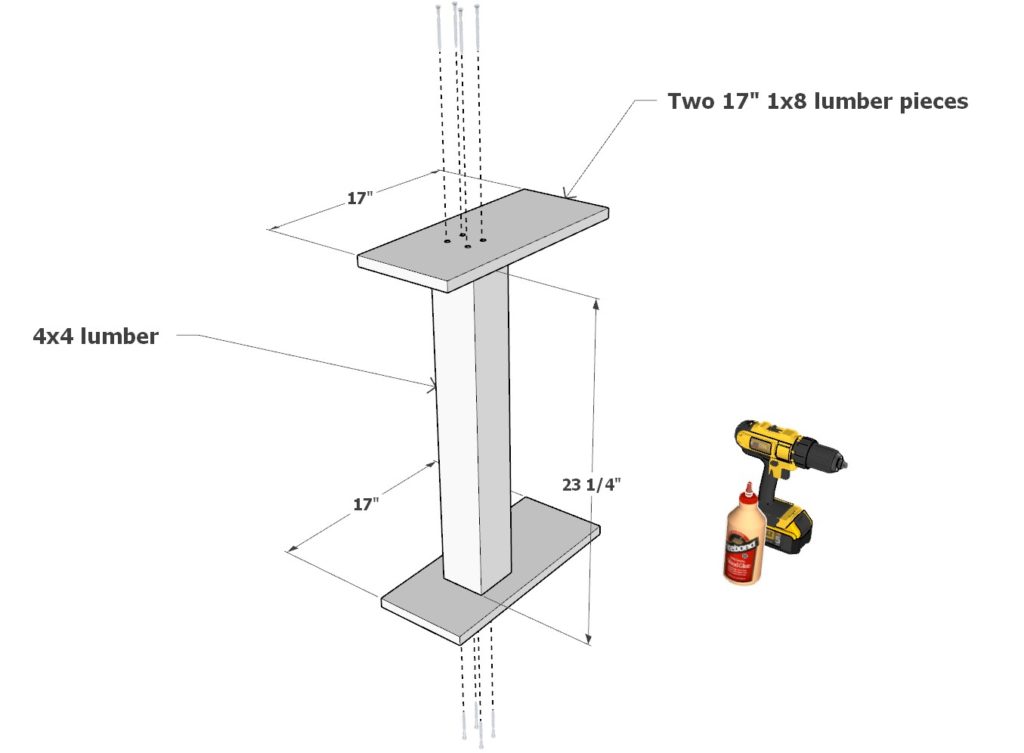

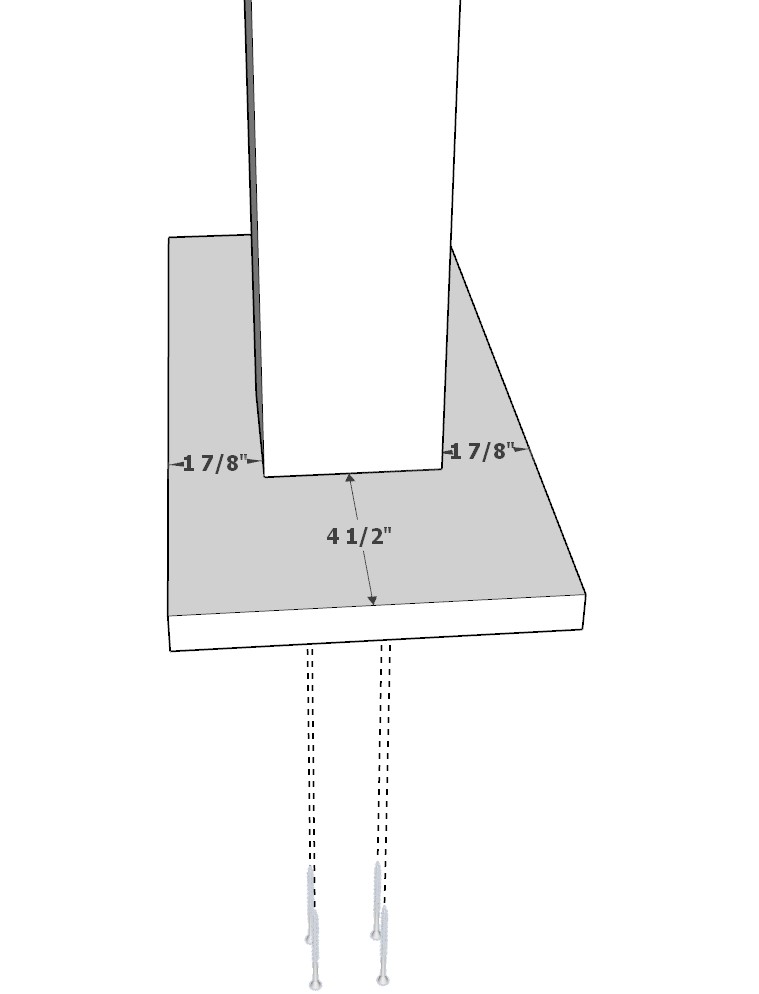

Constructing Individual Leg Components:

- Obtain a 23-1/4-inch long 4×4 lumber piece and two 17-inch long 1×8 lumber pieces.

- Arrange these pieces as illustrated in the first and second diagrams.

- Apply wood glue at the joints, predrill holes for enhanced stability, and firmly fasten them using 3-inch screws.

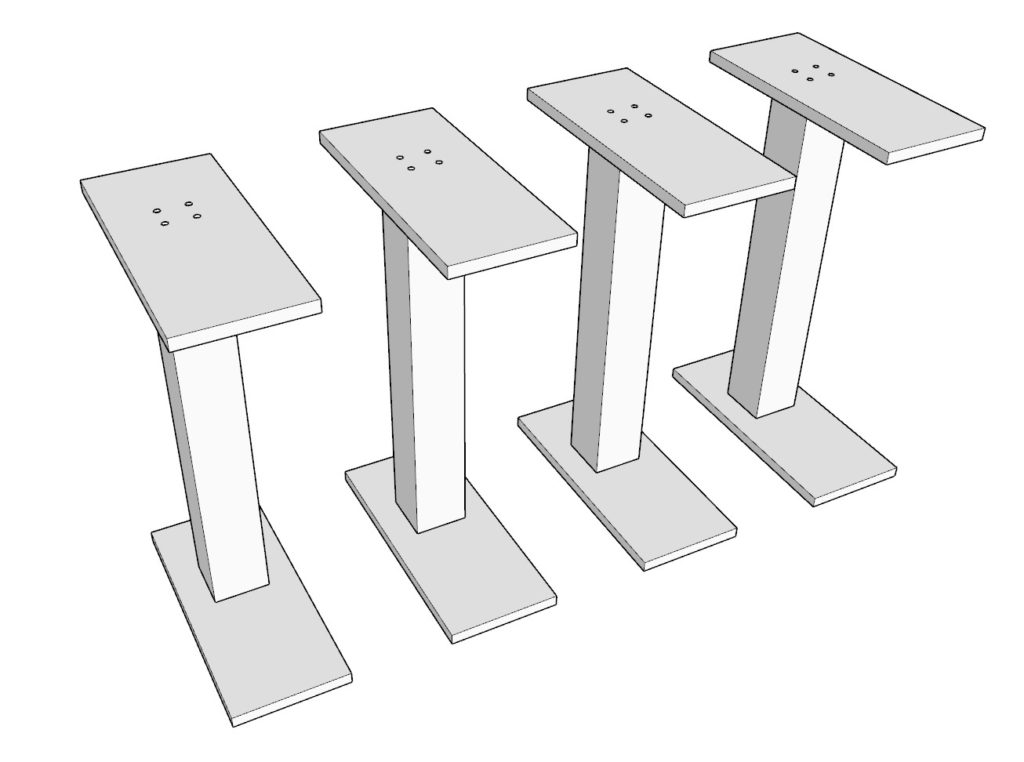

- Ensure you have four identical leg components by the end of this sub-step.

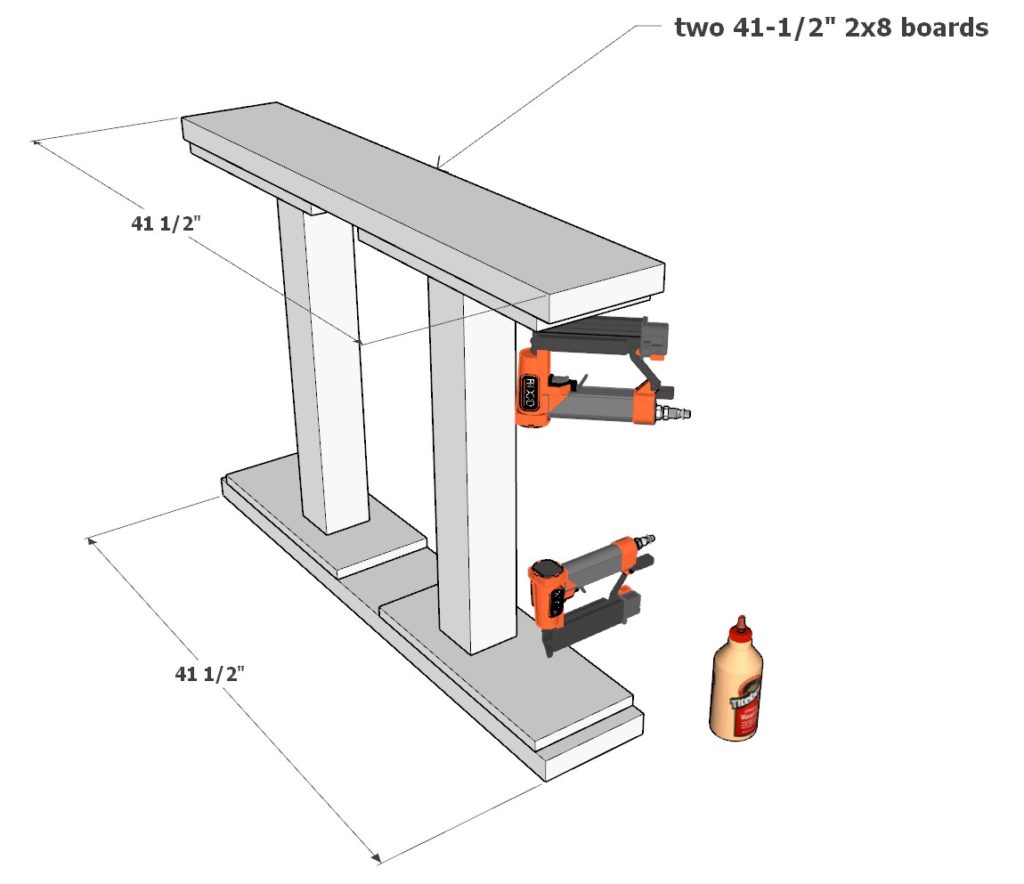

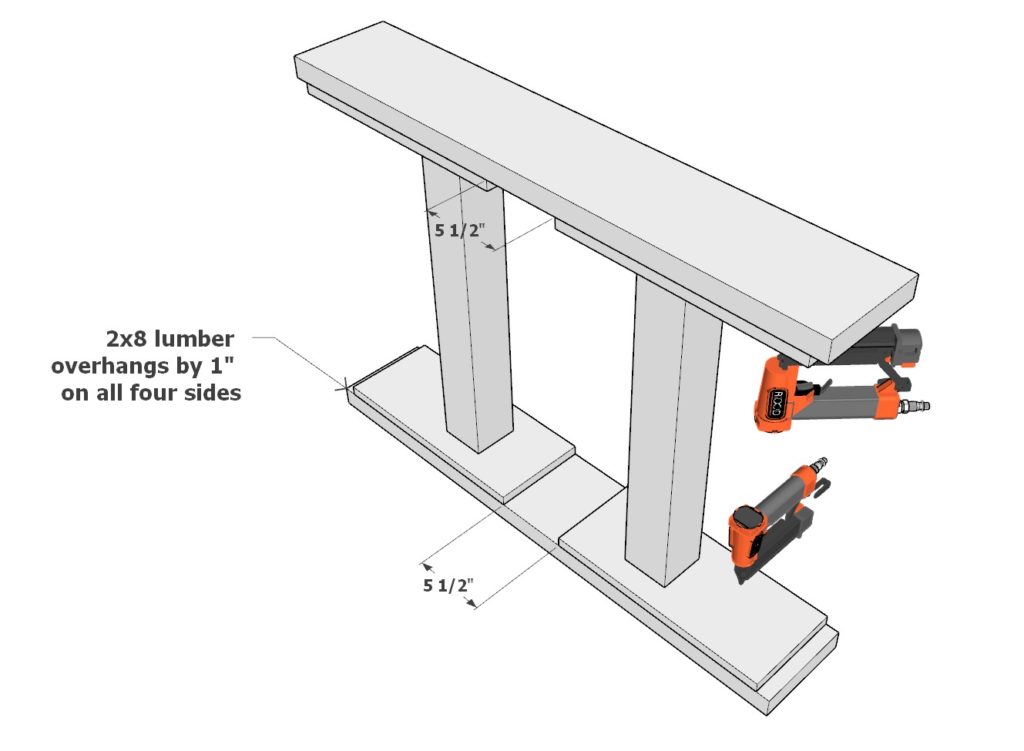

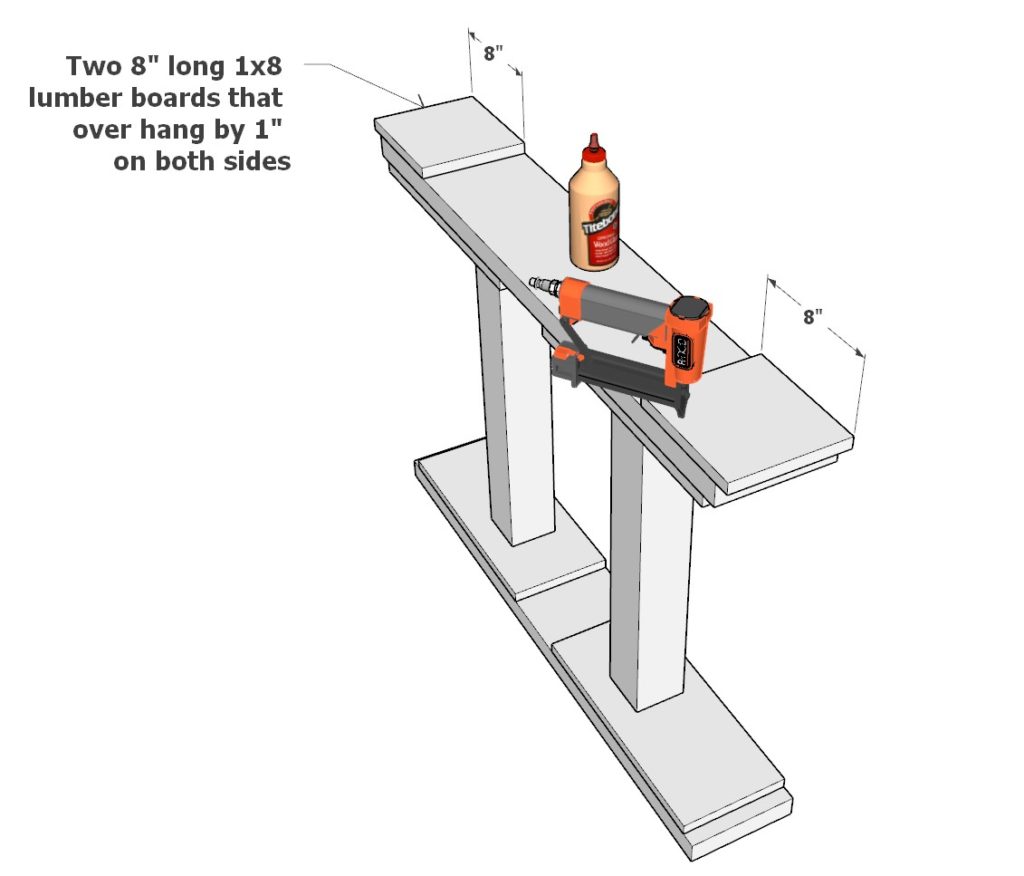

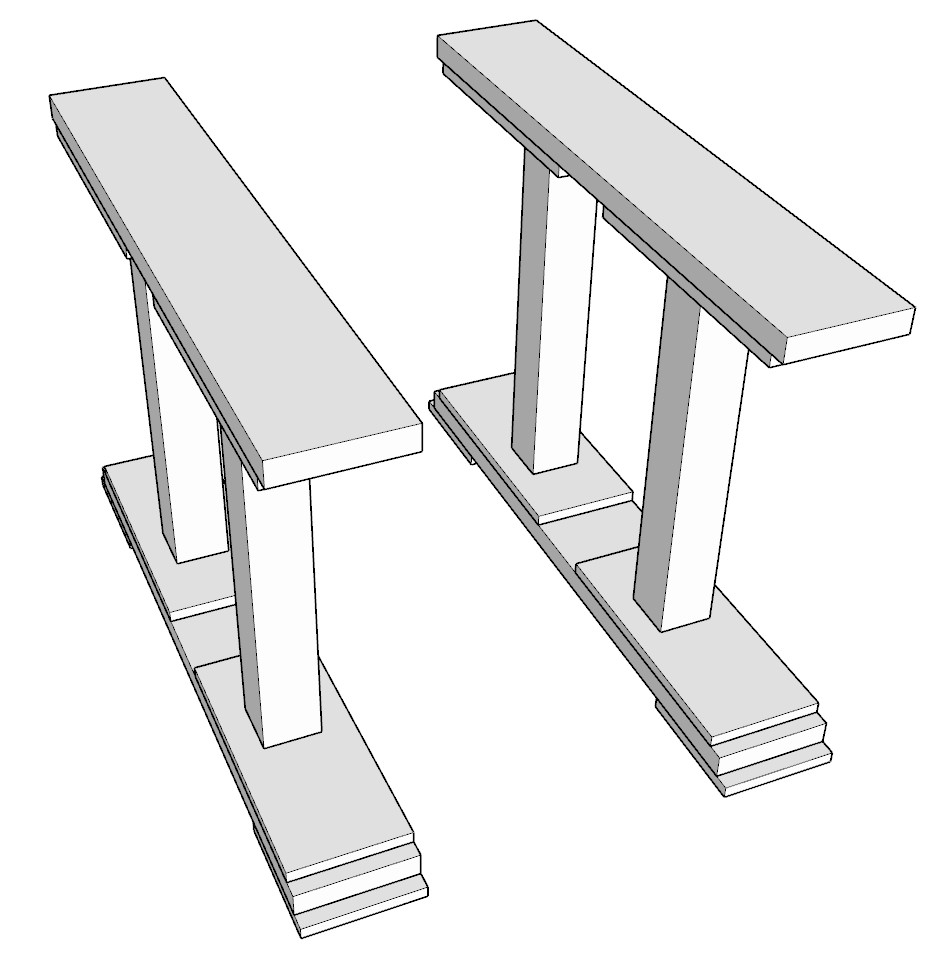

Assembling the Table Base Legs:

- Pair up two of the leg components from the previous step.

- Integrate them using two 41-1/2 inch long 2×8 lumber boards—one at the top and the other at the base of the paired leg components.

- Before attaching, measure to confirm the fitment for the stretcher.

- Upon verifying the measurements, glue and nail the pieces in place using 1-inch nails from a nail gun.

- To elevate the table and enhance its rustic charm, attach two 8-inch long boards to the bottom of this assembly, creating a subtle foot.

- Complete this process twice to yield two table base legs.

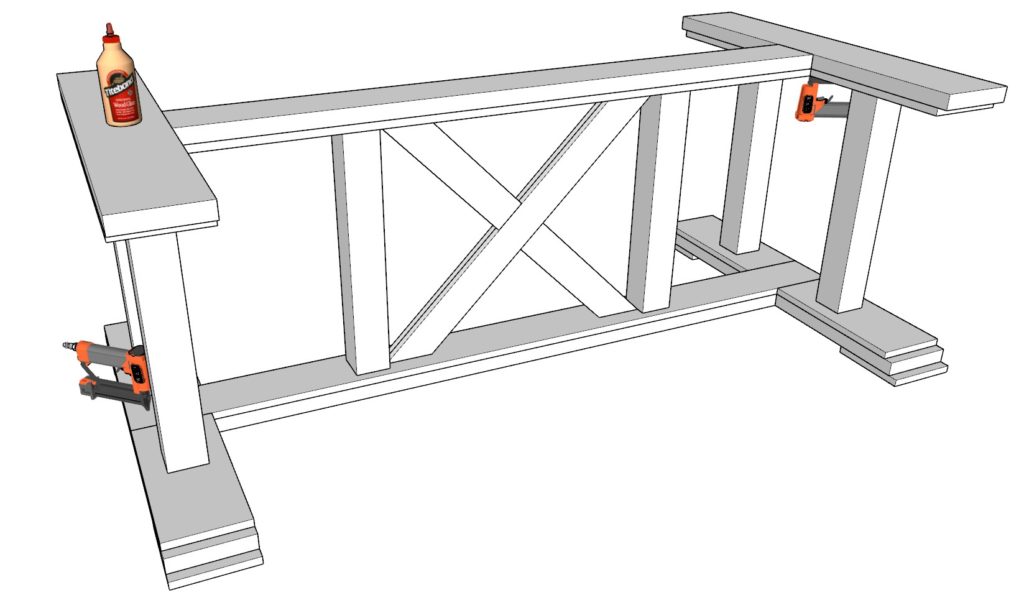

Joining Legs with the Stretcher:

- Position the two assembled table legs at the fitting distance.

- Attach them to the stretcher or beam using wood glue for a sturdy bond.

- Ensure everything is aligned and then use a nail gun to secure them with 1-inch nails.

Step 4: Crafting and Attaching the Tabletop

Establish a robust and stylish tabletop to complete your farmhouse table’s look.

Preparation of Lumber:

- Cut, sand, and plane all required lumber boards for the tabletop.

- Ensure each piece is smooth, preferably planed and sanded for an even finish.

Pro Tip: Before joining any components, lay everything out as per the diagrams. This helps visualize the final product and ensures precision.

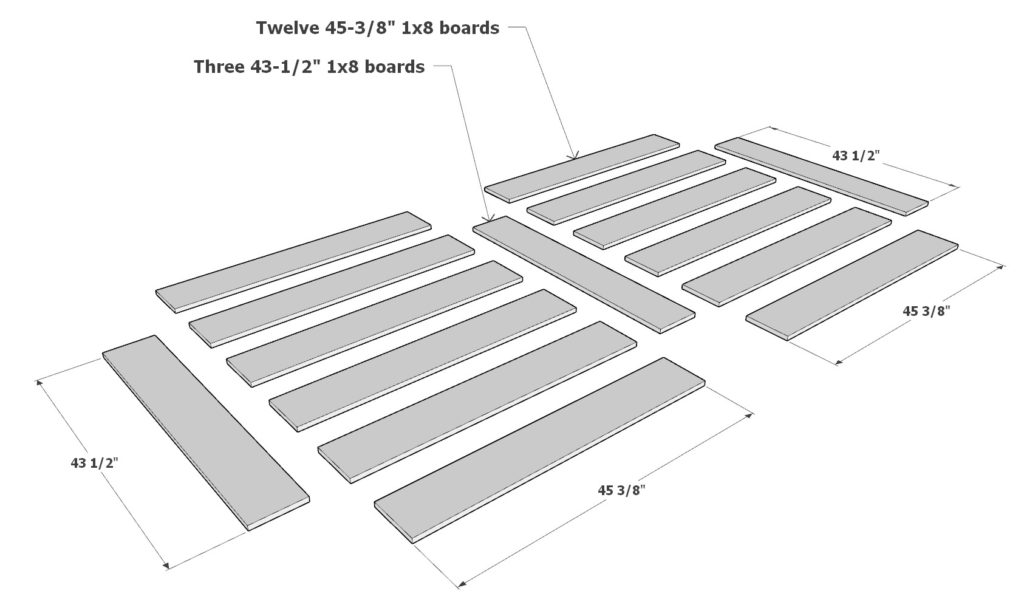

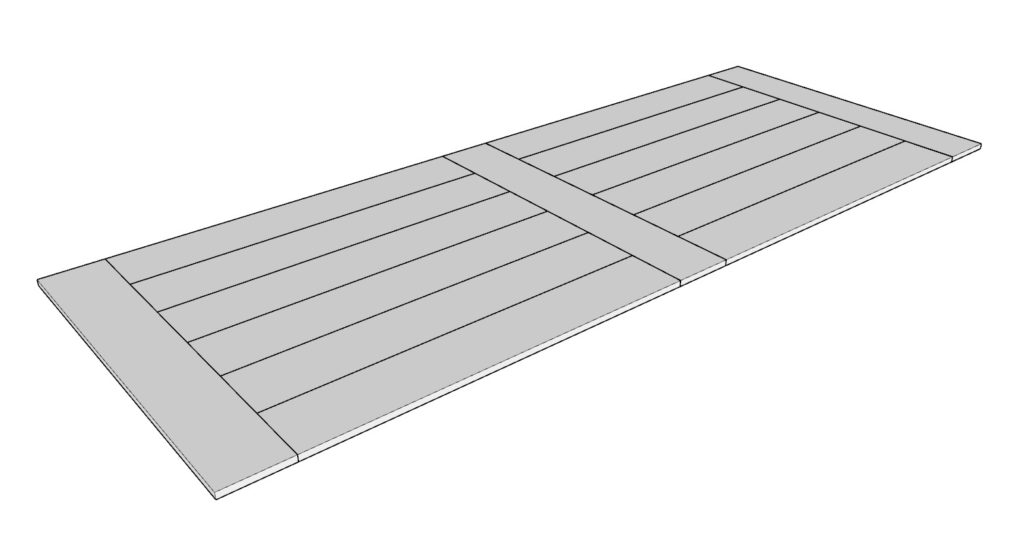

Assembling the Tabletop Base:

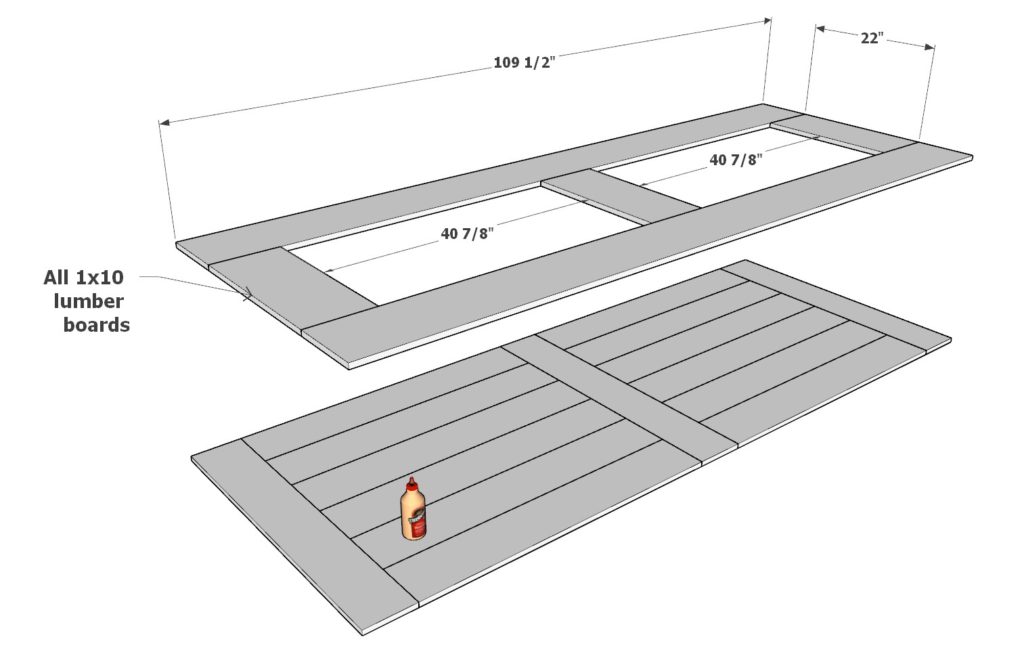

- Arrange twelve 45-3/8 inch long 1×8 boards and three 43-1/2 inch long 1×8 boards as illustrated in the diagrams.

- On top of this, position two 109-1/2 inch long 1×10 lumber boards and three 22 inch long 1×10 lumber boards.

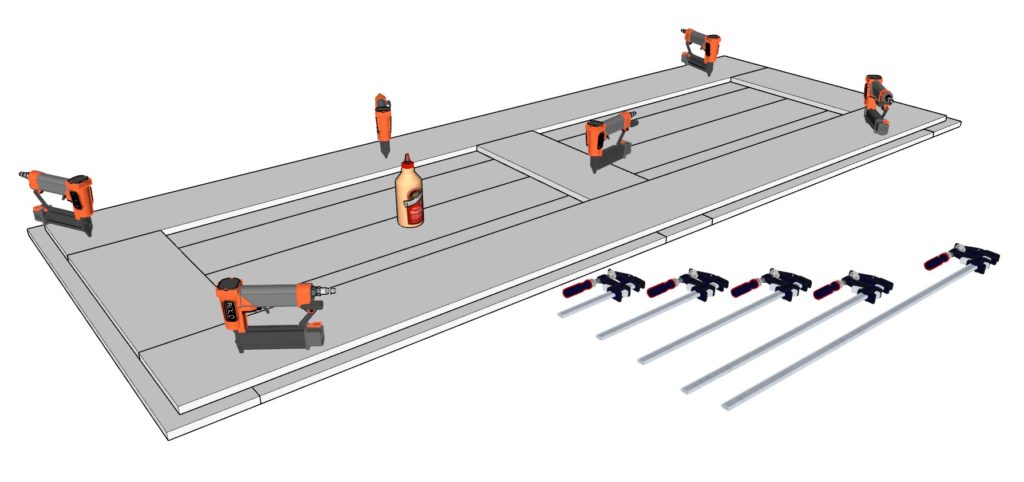

- Apply wood glue and fasten these pieces with 1-inch nails from a nail gun.

Pro Tip: Use wood clamps during assembly to ensure tight fits and eliminate gaps.

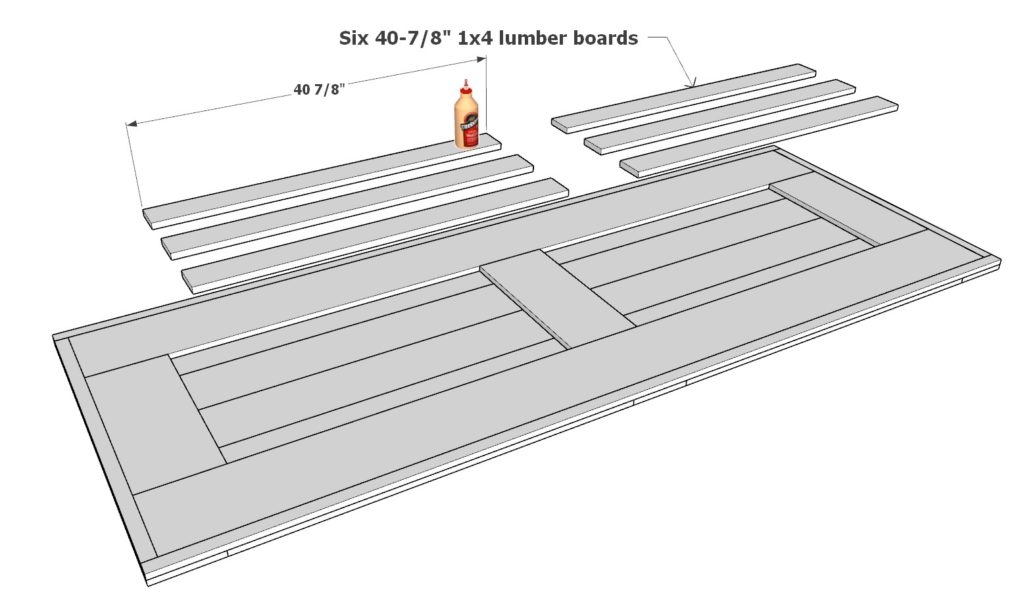

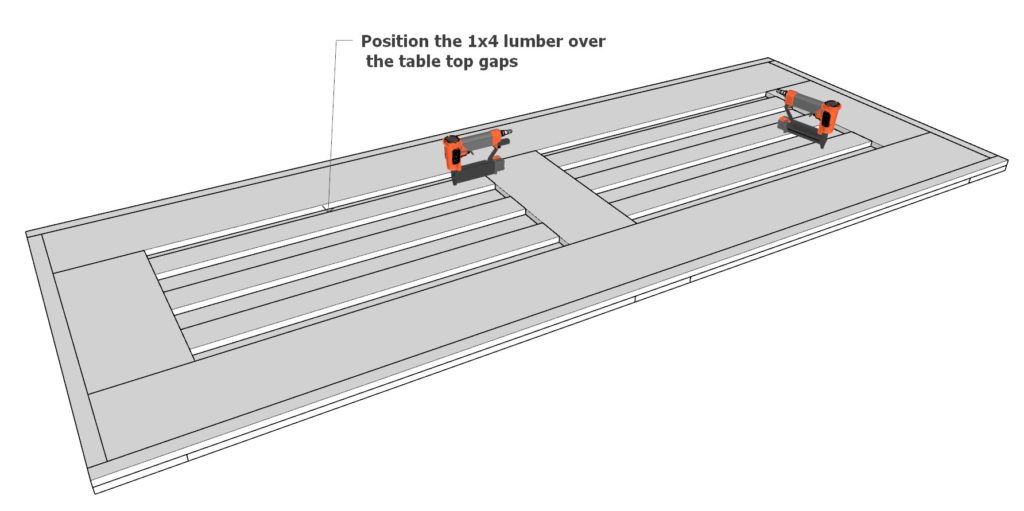

Filling Gaps and Refining Edges:

- Place six 40-7/8 inch long 1×4 lumber boards where necessary, as shown in the diagrams, to prevent any future separations or gaps.

- Secure these fillers with wood glue and 1-inch nails.

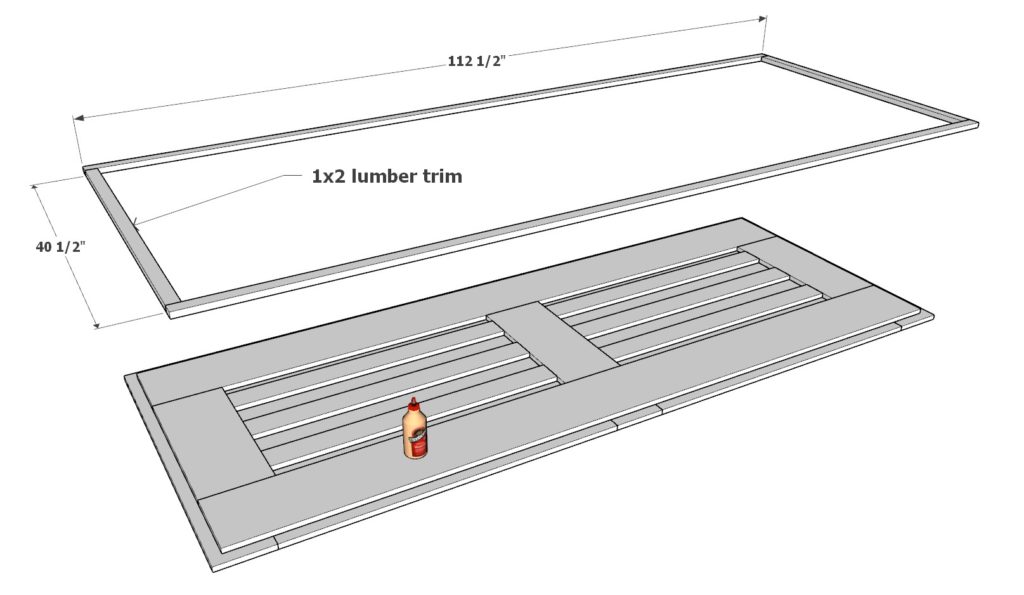

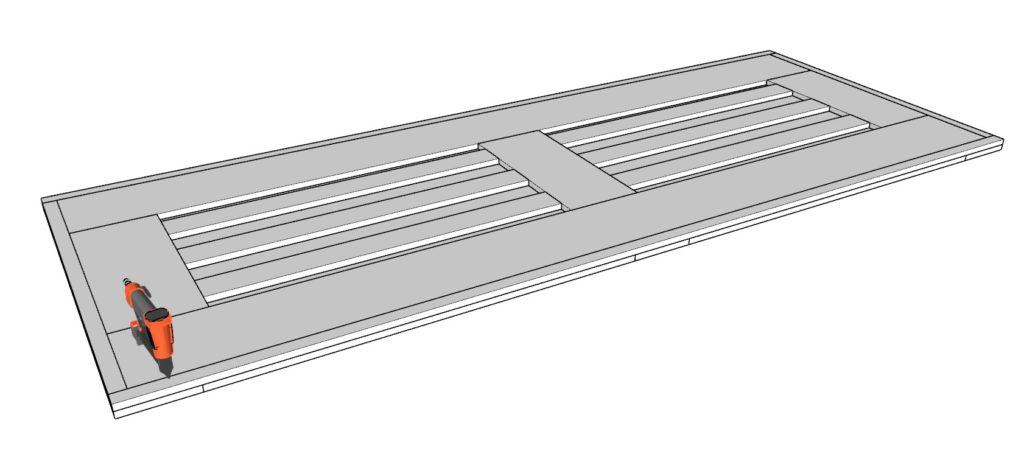

- To give the tabletop a polished edge, attach a 1×2 lumber trim. This requires two 112-1/2 inch long 1×2 pieces and two 40-1/2 inch long 1×2 pieces. Fix them using wood glue and 1-inch nails.

Pro Tip: For any overhanging edges, utilize a circular saw for a neat finish. Consider using a router on the tabletop edges for a rounded, non-abrasive finish.

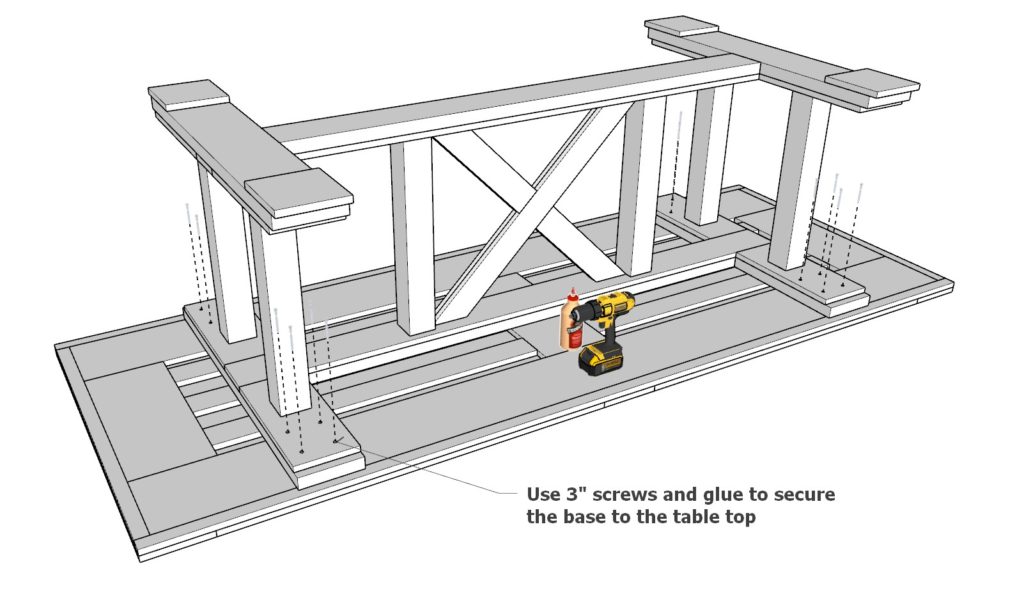

Mounting the Tabletop:

- Align the crafted tabletop with the table base.

- Secure the connection using 3-inch screws, and if preferred, wood glue.

Pro Tip: For portability, you might opt to skip the glue. This allows the tabletop and base to be separated, making it easier for transportation or rearrangement, albeit slightly less stable.

Step 5: Finishing Touches and Refinements for Your Farmhouse Table

Before diving in, always ensure you’re working in a well-ventilated area and wearing appropriate safety gear like gloves, masks, and safety glasses.

Sanding:

- Begin with coarse sandpaper (80-grit) to tackle any major imperfections. Transition to finer grits, up to 220-grit, for a polished finish.

- Use an orbital sander for vast surfaces. For precision on edges and intricate areas, opt for handheld sanding blocks or sponges.

Safety Tip: Always sand in the direction of the grain to avoid splinters.

Routing Edges:

- Soften sharp corners or edges, especially on the tabletop, with a router for enhanced safety and a polished finish.

Distressing Techniques:

- Wire Brushing: Brush along the grain for an aged texture.

- Hammer and Chain: Create authentic dents and divots.

- Screw and Nail Head Impressions: Produce small, controlled dents.

- Scraping Edges: Emulate natural wear, especially on corners.

Pro Tip: Pairing multiple distressing techniques can yield a more authentic rustic appearance.

Covering Nail Holes:

- Wood Filler: Ensure it’s stainable to match the surrounding wood.

- Sawdust and Glue: A homemade solution for better color matching.

- Embrace Them: Nail holes can add to the rustic charm.

Staining:

- Prep the wood with a tack cloth to remove dust.

- Apply a wood conditioner for even stain absorption.

- Test the stain on scrap wood first. Once satisfied, apply in the direction of the grain.

- Wipe away excess after a few minutes and apply additional coats if a darker finish is desired.

Achieving a Harmonious Color on Different Woods:

- Layered Staining: Multiple coats can help different woods match better.

- Wood Conditioner: Essential for woods like pine that might stain unevenly.

- Natural Finish: Sometimes, different woods naturally harmonize.

- Strategic Placement: Differences might be less visible depending on the table’s design.

Painting:

- Prime first for better paint adherence.

- Opt for semi-gloss or satin finishes for their look and durability. Apply in thin coats, sanding lightly in between.

- Finish with a protective topcoat for longevity.

Additional Tips:

- When using tools or chemicals, always refer to the manufacturer’s safety guidelines.

- It’s essential to let paint and stain dry thoroughly before adding additional coats or using the table. This ensures durability and the best finish.