Introduction: Why Build Your Own Patio Set?

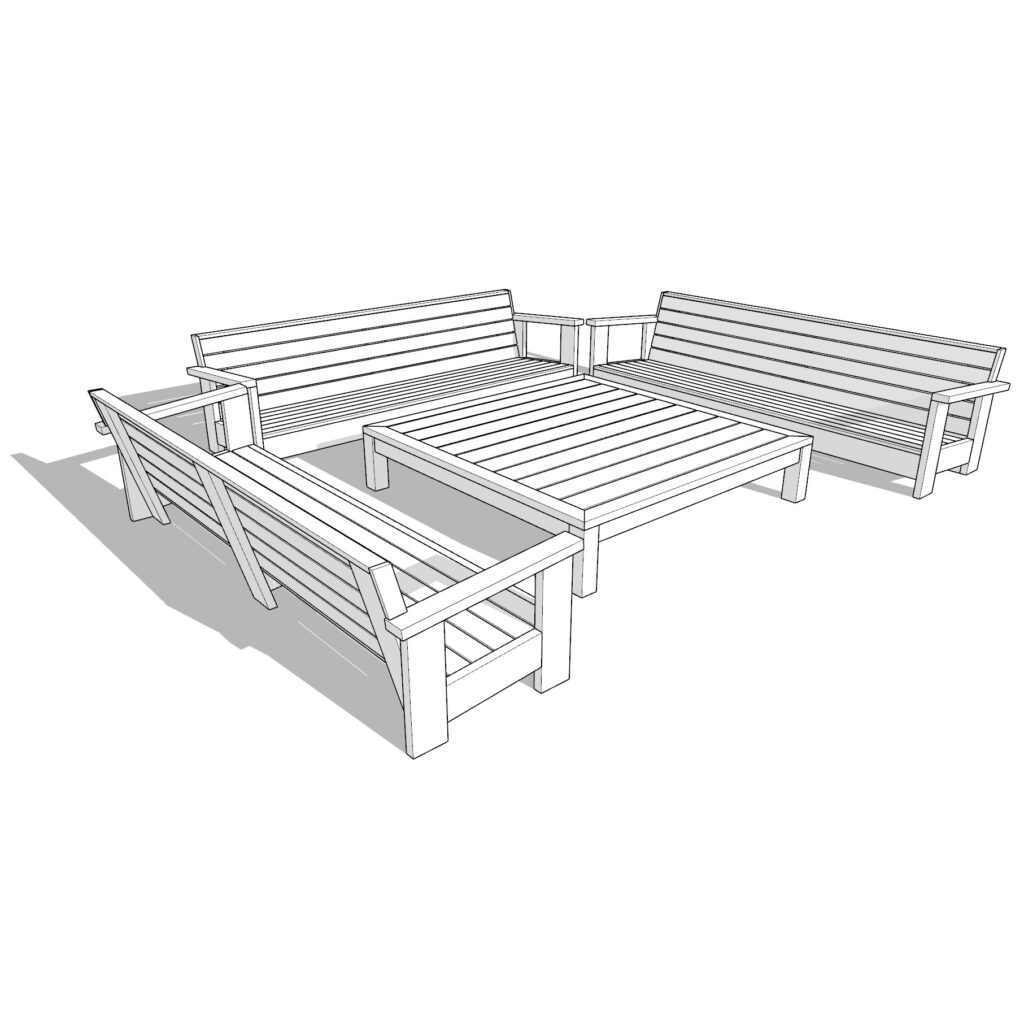

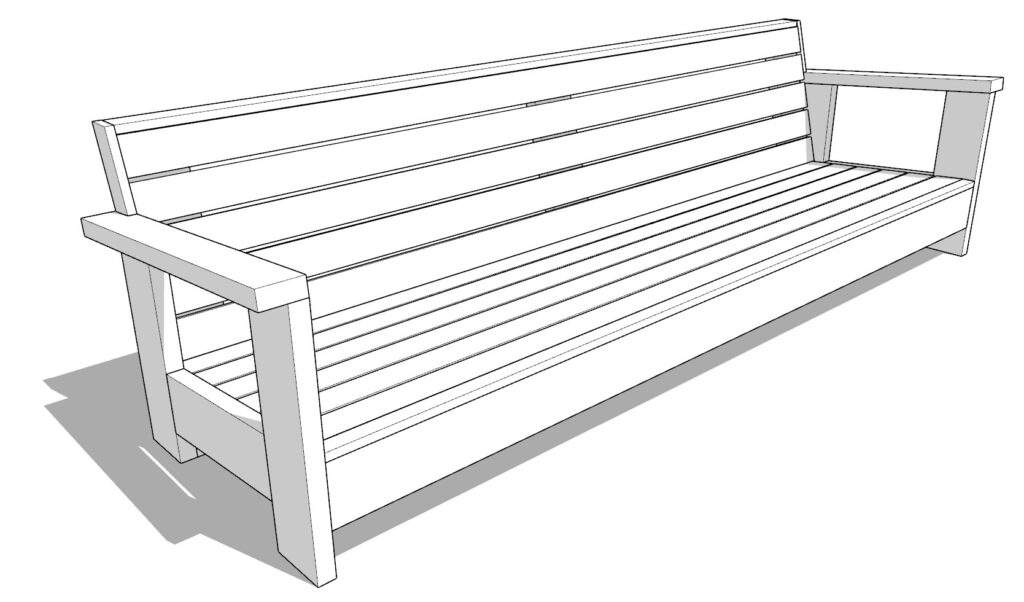

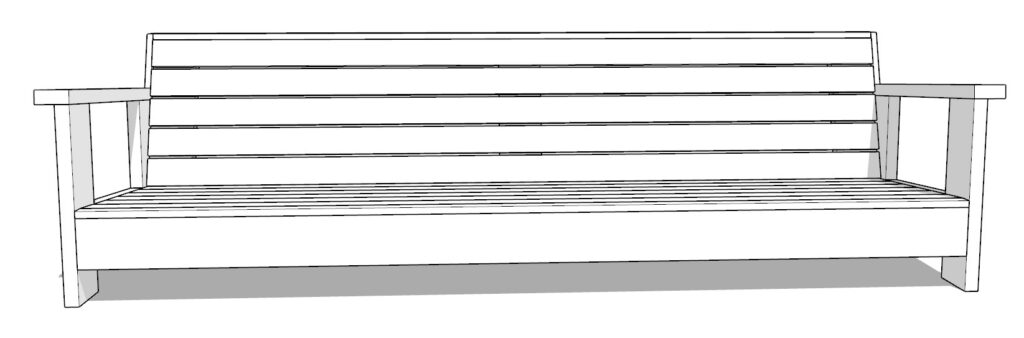

Imagine the warm glow of sunset on your face, a cool breeze in the air, and the soft murmur of nature around you as you recline on a bench you’ve built with your own hands. This isn’t just any bench—it’s part of a spacious, ergonomic patio set that’s the new centerpiece of your backyard oasis. Building your own furniture isn’t just about crafting pieces that fit your space perfectly; it’s about creating memories and a sense of accomplishment that comes from DIY mastery. This patio set isn’t just a place to sit; it’s a personal retreat where every board and cushion reflects your hard work and creativity.

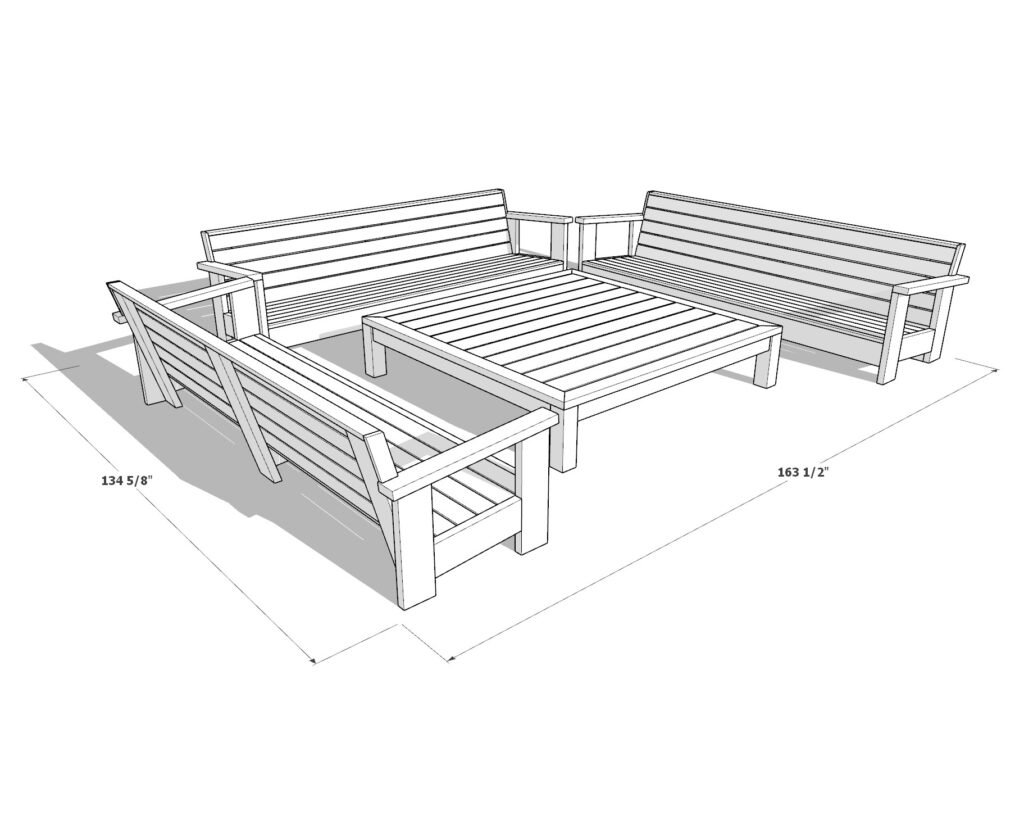

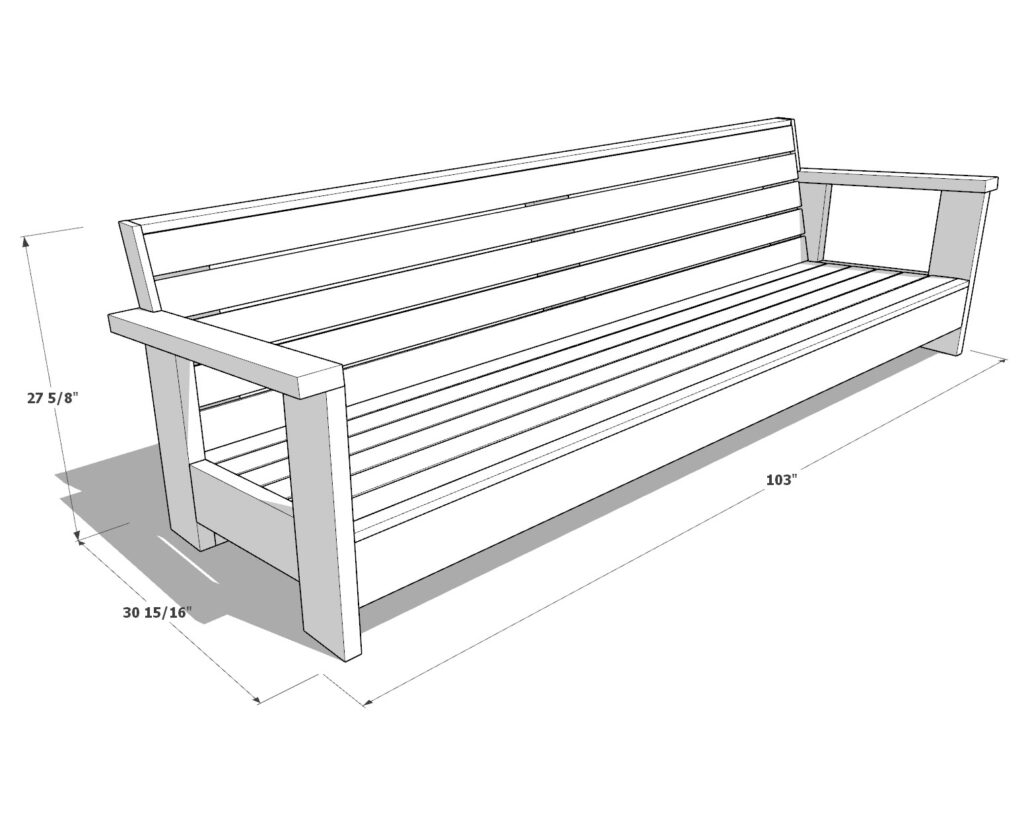

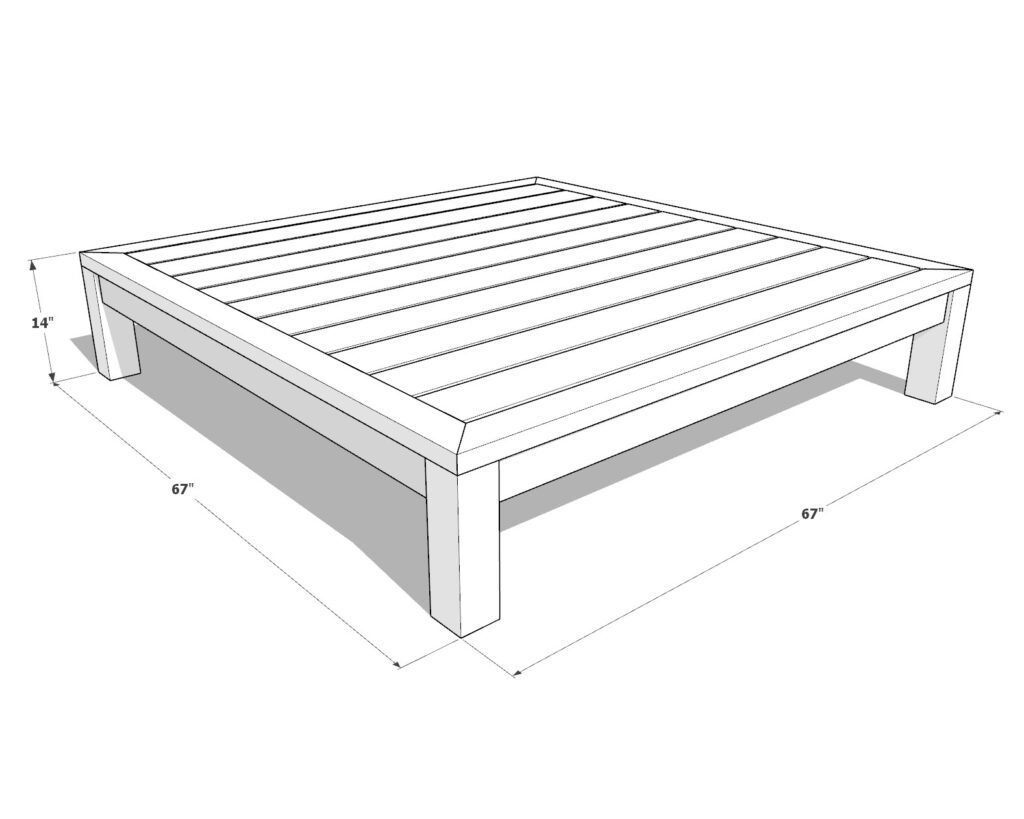

Specifications: The Comfort and Size That Fit

Our patio set stands out with its generous dimensions and thoughtfully designed ergonomics. The bench is a substantial 103 inches of comfort, paired with a depth of 31 inches and a height of 28 inches, accommodating friends and family without feeling crowded. The backrest reclines at a 105-degree angle, and the seating area is tilted at a 5-degree incline—subtle adjustments that make all the difference in comfort. The accompanying table, a grand 67-inch square and 14 inches tall, anchors the set, ensuring ample space for everything from summer cocktails to board games. It’s large, it’s in charge, and it’s the perfect hub for your next gathering.

Beginner Friendliness: What You’ll Receive with Our Plans

Our DIY plans are a beacon for beginners. They illuminate the path from raw materials to finished product with clarity and ease. You’ll receive a comprehensive cut list, a detailed shopping guide, and a robust list of required tools. Each plan is a masterclass in organization, complete with color-coded instructions, vivid images, and precise diagrams that make each step clear and achievable. Our no-nonsense, straightforward language ensures that you’ll never feel lost or overwhelmed. We lay the groundwork so you can build with confidence.

Cushions and Lumber Sourcing: The Ease of Preparation

One of the finest features of this patio set is the ease with which you can source materials. The cushions—a plush 24×24 inch—are a standard size, readily available at your favorite retailers like Home Depot, Lowe’s, Amazon, and Target. As for the lumber, we stick to the basics: standard 2×6 and 2×4 construction lumber, materials you can pick up from any local hardware store. This project is about minimizing hassle and maximizing enjoyment, from procurement to the final product.

Conclusion: More Than Plans, A Step Toward Your Dream Backyard

This isn’t just about buying plans; it’s about taking a step towards the backyard of your dreams. It’s about the pride of creating something durable, stylish, and comfortable with your own two hands. We’re here to help you build your dream patio set, one plank at a time. So, if you’re ready to turn your outdoor space into a haven for relaxation and entertainment, grab our plans and get started on a journey that ends with “Wow, I made this.”

Time

(varies with experience)

Cost

Estimated Project Cost: $450 (Note: Costs can vary by location and supplier. This estimate covers lumber for 3 benches and 1 table, excluding cushions.)

Skill level required

Beginner

DIY Patio Set PDF Plan

What is included in the PDF download?

- Easy to read step by step instructions

- Material list

- Tools needed

- Helpful links to materials and tools needed

Tools and Materials (Bench):

Available with the purchase of the DIY plan PDF.

Lumber Shopping & Cut List (Bench):

Available with the purchase of the DIY plan PDF.

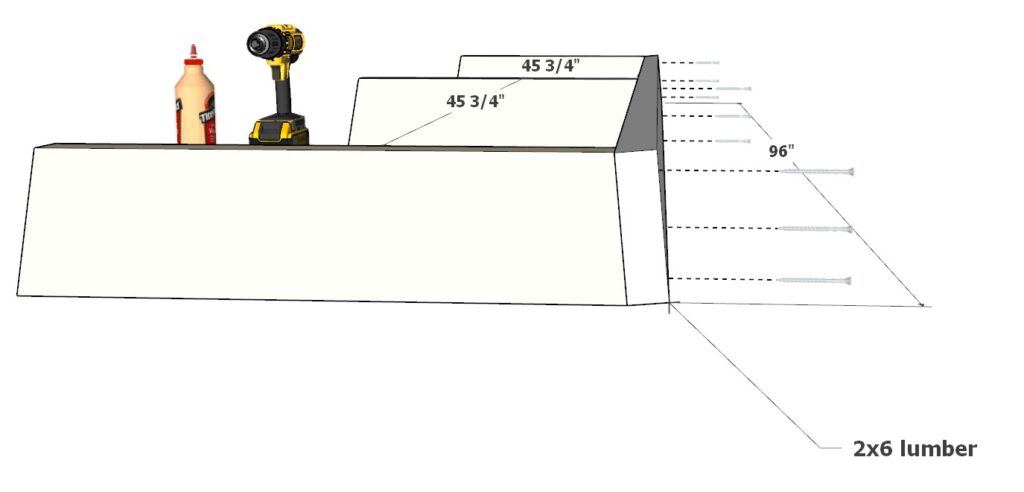

Step 1: Constructing the Main Frame of the Patio Bench

Build the Seating Platform Frame

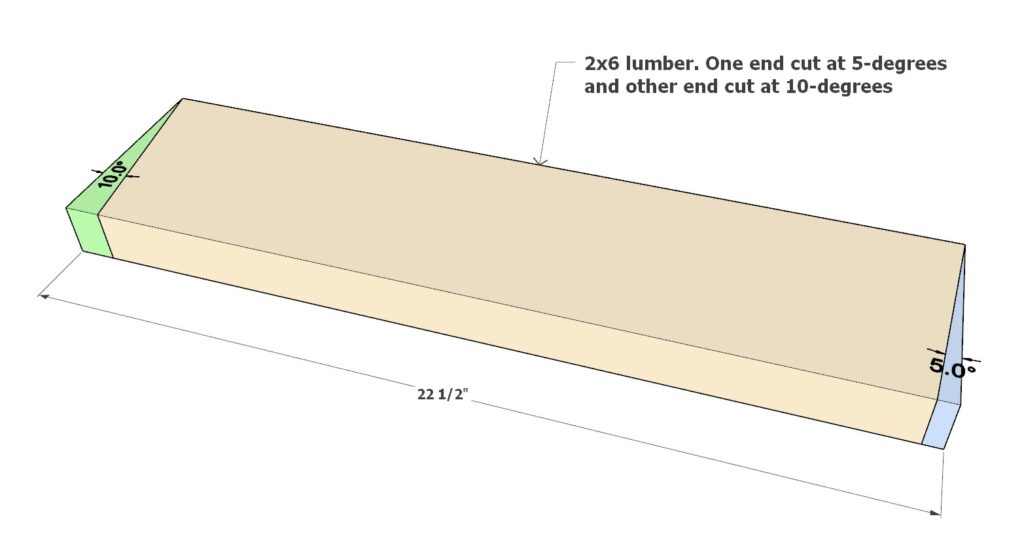

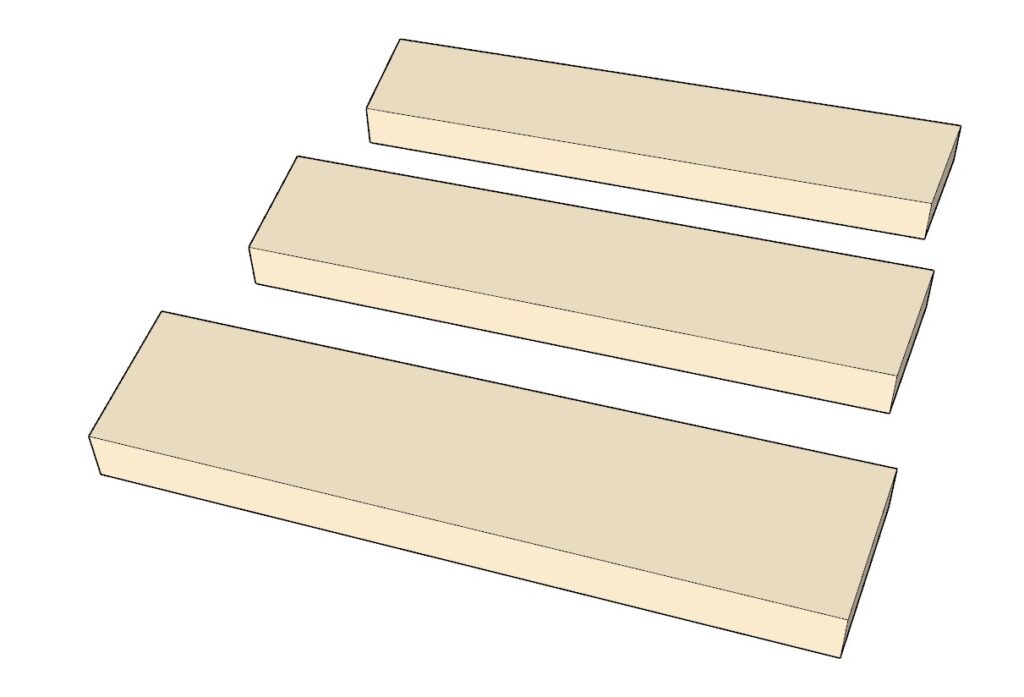

- Prepare the Wood Pieces: Start by taking three pieces of 2×6 lumber, each measuring 22-1/2 inches in length. Each piece is color-coded in pale peach for easy identification.

- Cut the Angles: On one end of each pale peach board, cut a 5-degree angle, and on the opposite end, cut a 10-degree angle. These cuts will allow the boards to fit together at the right angles for comfort.

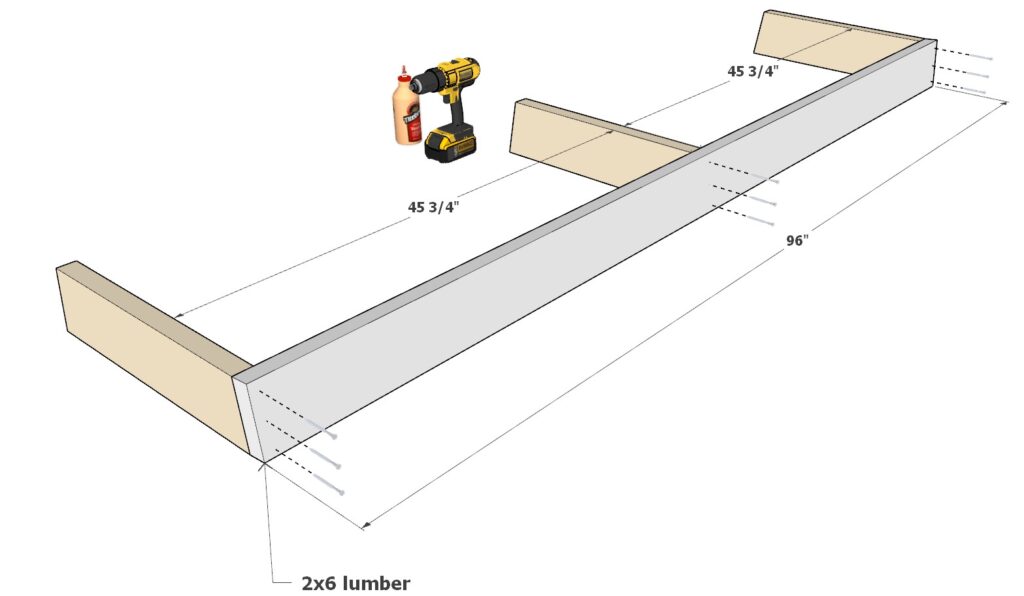

- Assemble the Frame: Attach these three pale peach boards to a 96-inch 2×6 lumber board, following the layout shown in the diagram. Use 3.5-inch screws and wood glue to secure them together.

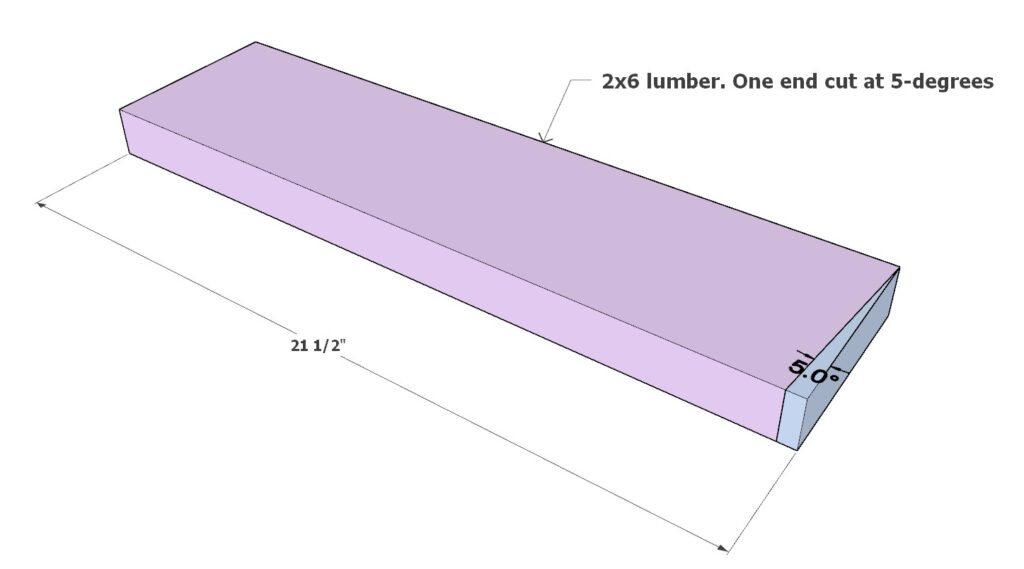

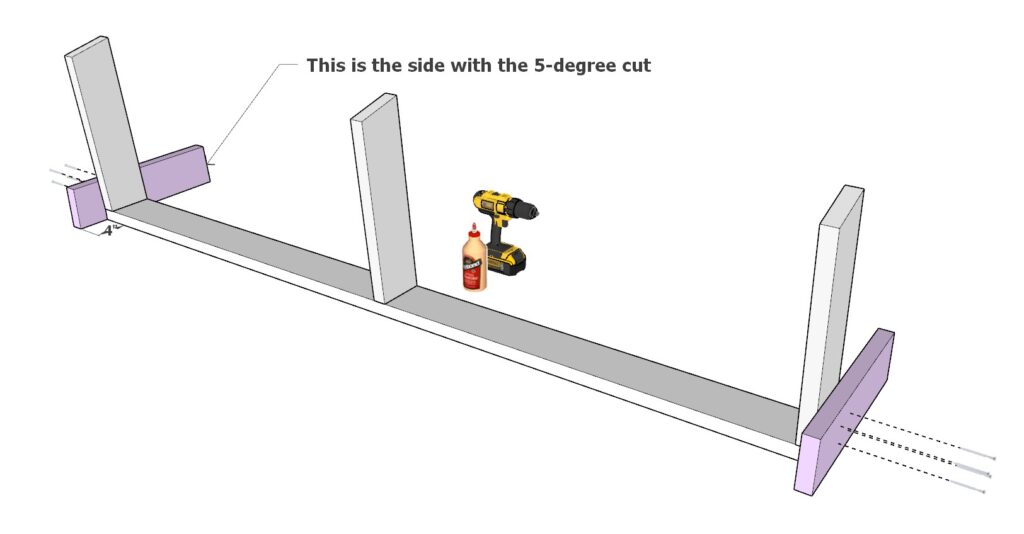

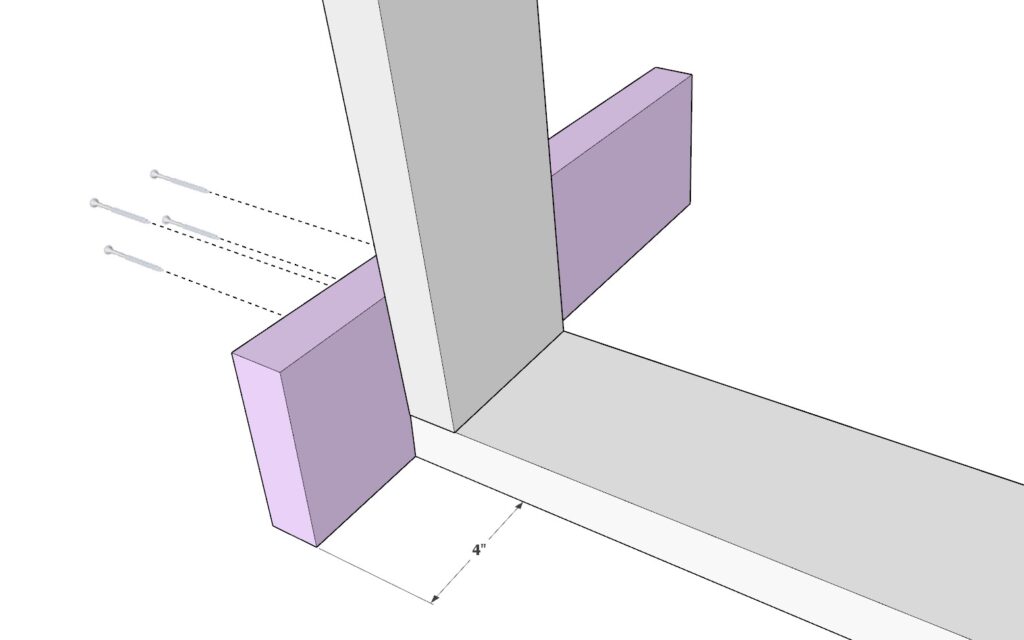

Attach the Front Legs

- Prepare the Front Legs: Get two pieces of 2×6 lumber, each 21-1/2 inches long, color-coded lavender.

- Cut the Front Legs: Cut one end of each lavender board at a 5-degree angle.

- Secure the Legs: Fasten these two lavender boards to the seating platform frame you just built. Make sure to use 2.5-inch screws, which are the right length to hold firmly without sticking out the other side. Apply wood glue for additional strength.

Install the Back Legs

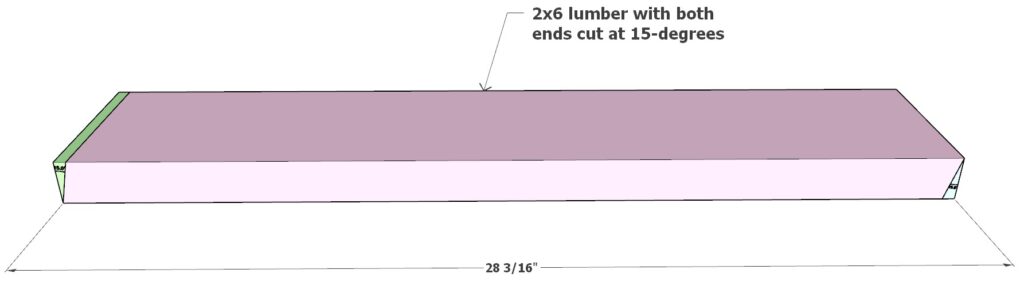

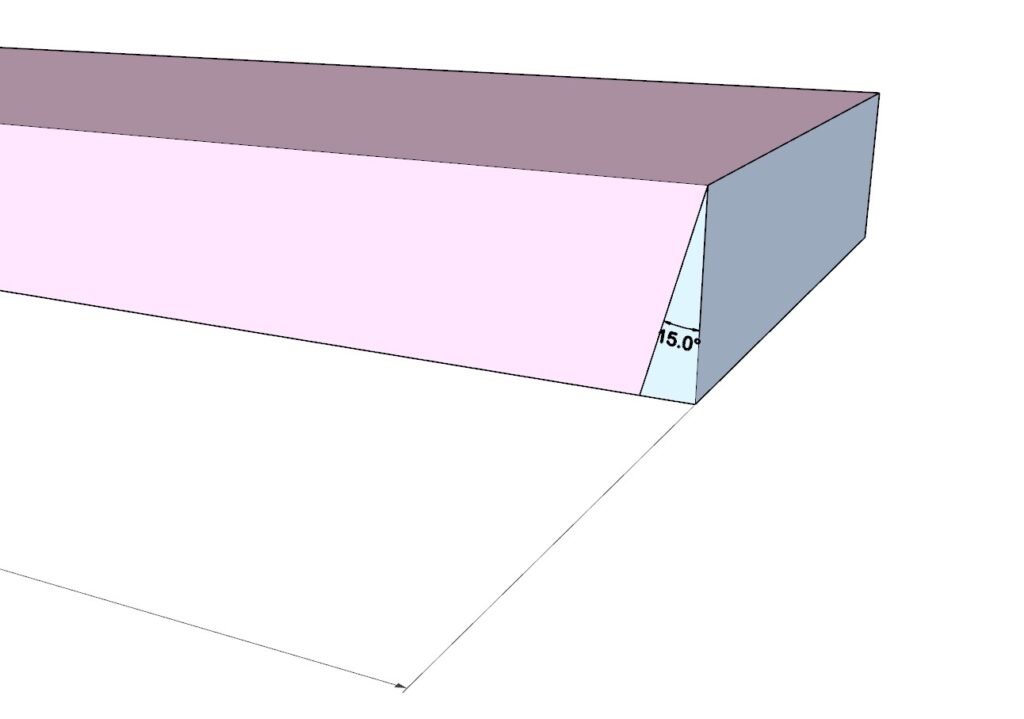

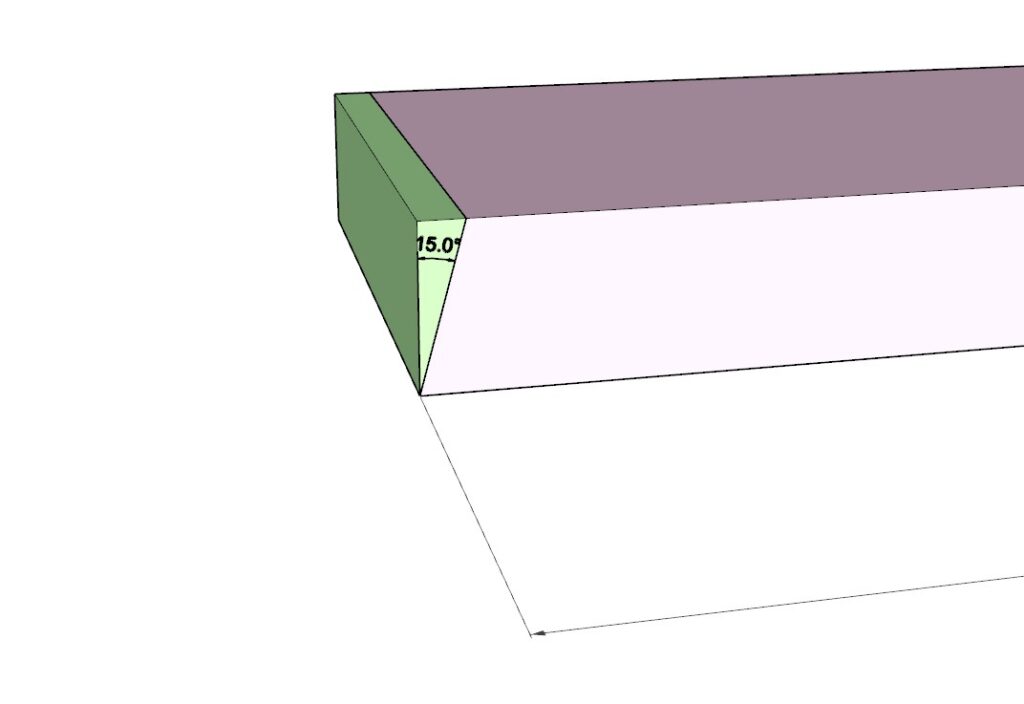

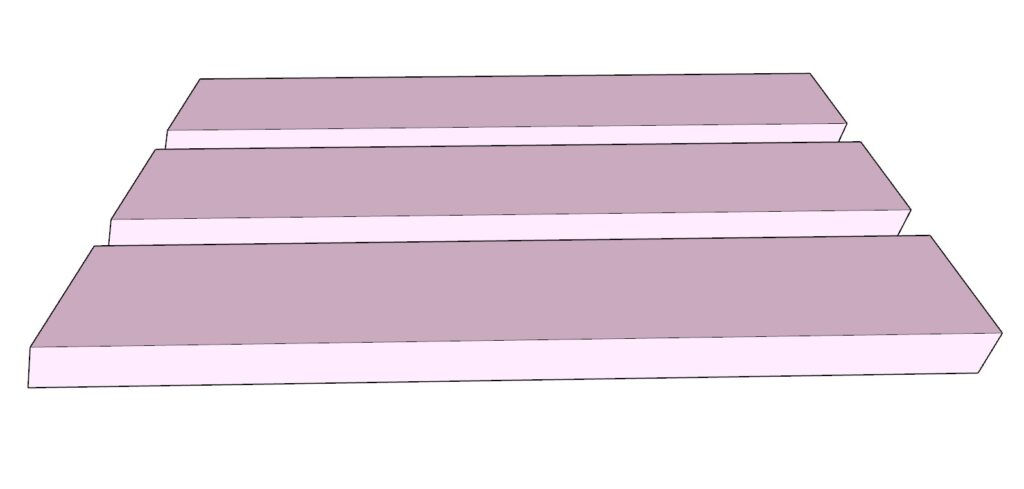

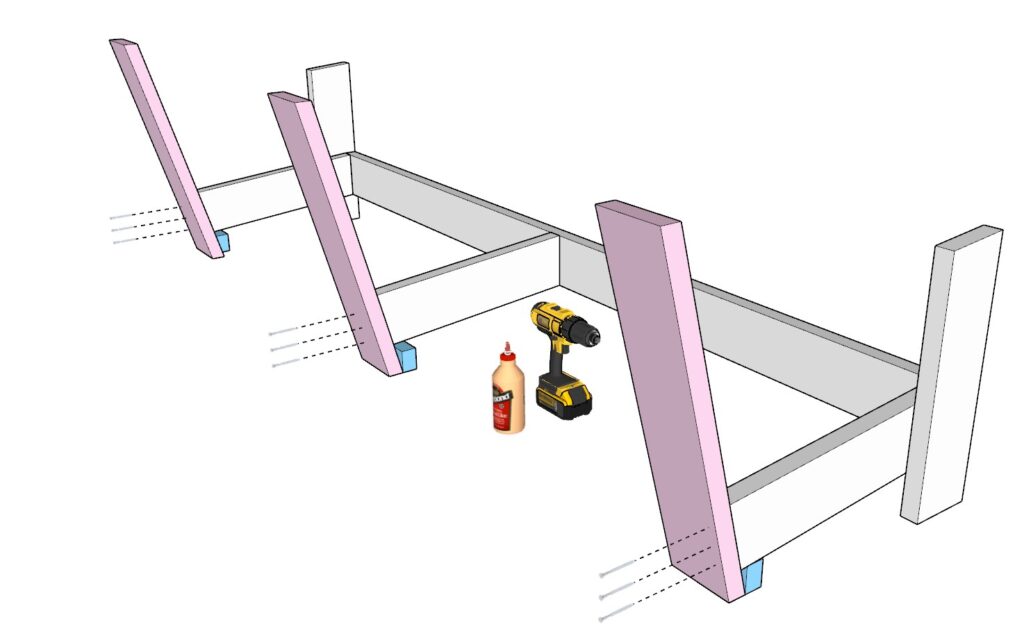

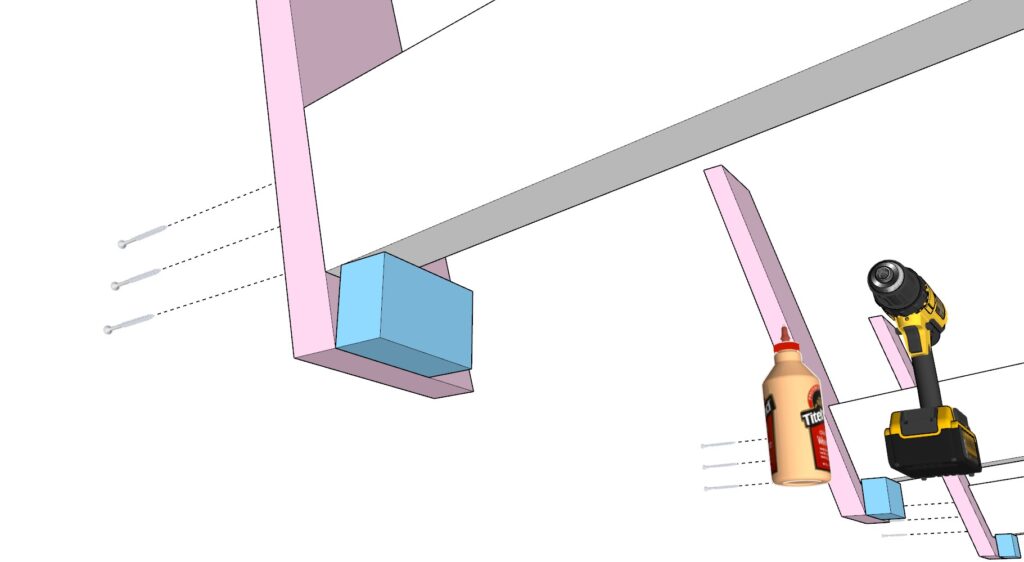

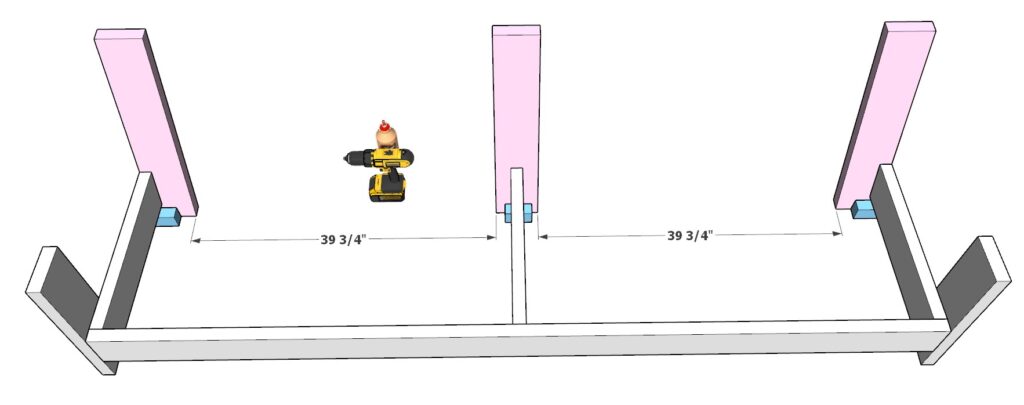

- Prepare the Back Legs: Take three 2×6 lumber boards, each 28-3/16 inches long, color-coded pink.

- Cut the Back Legs: Cut both ends of each pink board at a 15-degree angle.

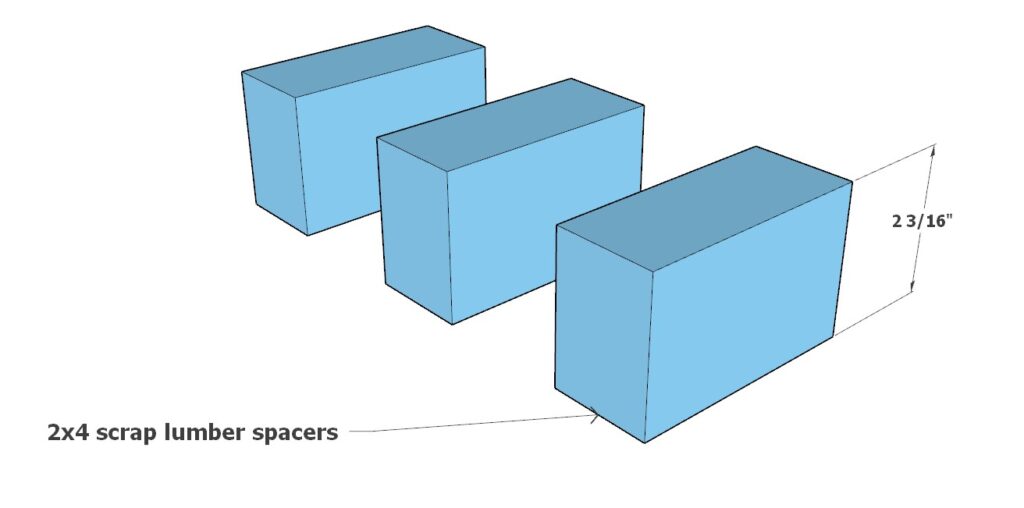

- Make and Use Spacers: Cut three spacers from any scrap lumber, each 2-3/16 inches tall, color-coded blue. These spacers will help you attach the pink boards at the correct height on the seating platform.

- Attach the Back Legs: Place the blue spacers as illustrated in the diagram, and then attach the pink boards to the seating platform frame with 3.5-inch screws.

Handy Tips:

- Pre-Drill for a Clean Finish: To prevent the wood from splitting, pre-drill the holes with a countersink drill bit. If you plan to fill the screw holes with dowels for a smooth look, as shown in the model photos, pre-drill the holes to the size needed for the dowels.

- Smooth the Surface: Plane and sand all the wood pieces before assembly. This will make sure they are smooth and clean, saving you the trouble of sanding in hard-to-reach places later on.

Step 2: Adding Support and Arm Rests to the Frame

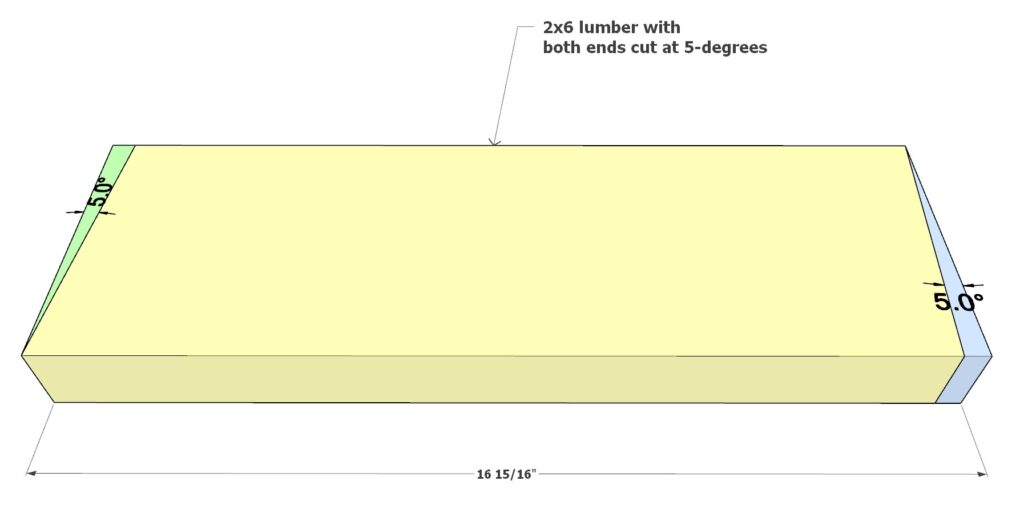

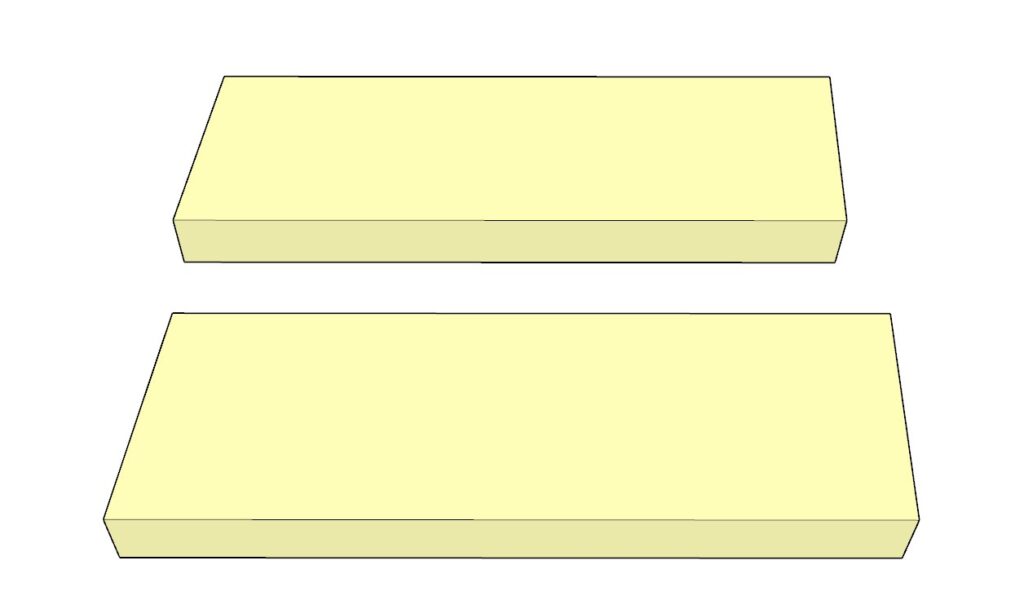

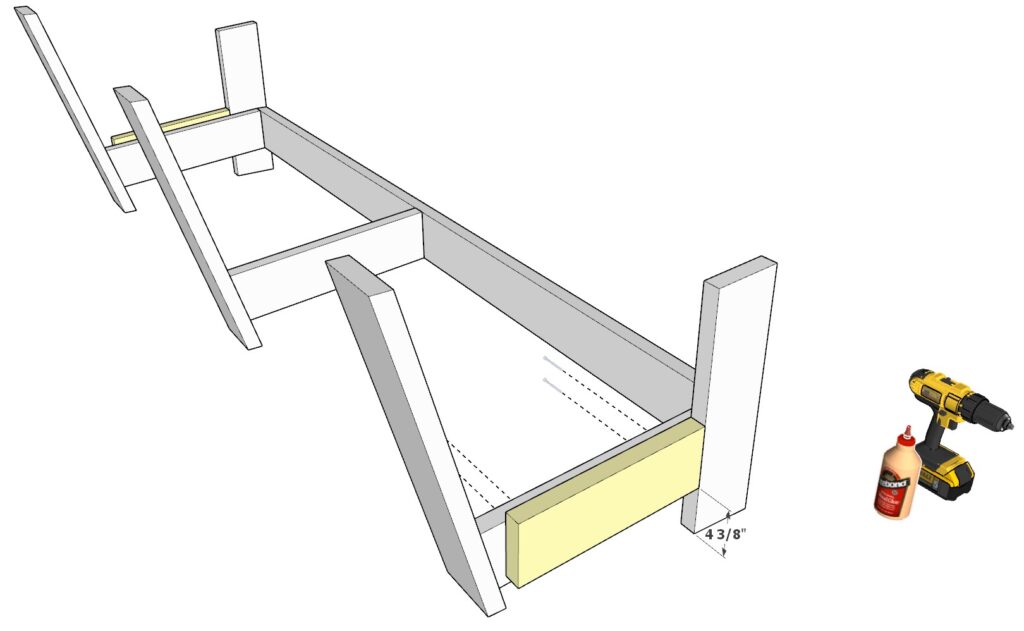

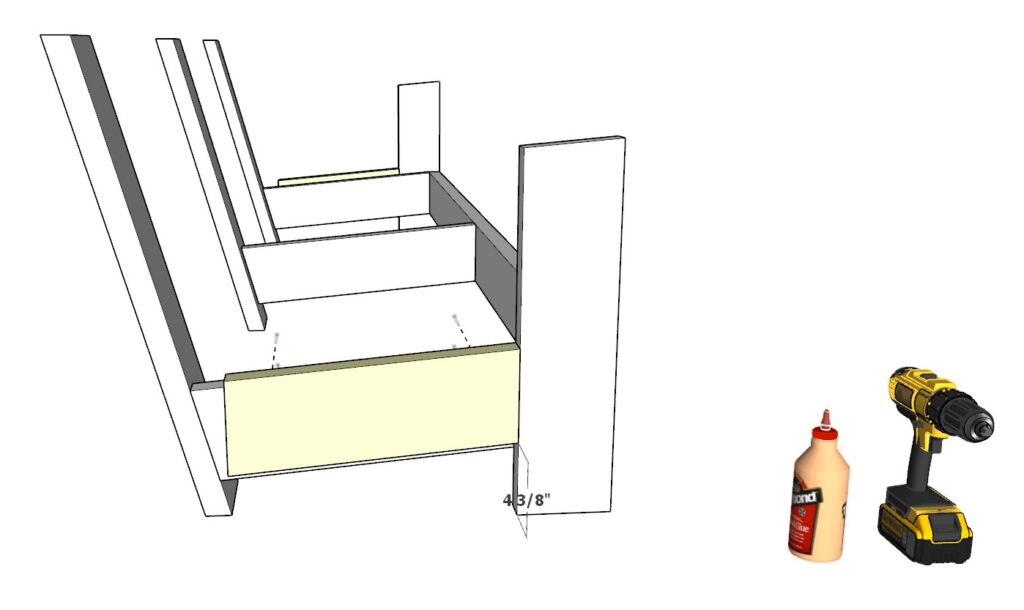

Strengthen the Arm Rests and Legs

- Prepare the Support Pieces: Take two pieces of 2×6 lumber, each 16-15/16 inches long. Color-coded yellow for easy identification.

- Cut the Angles: Cut both ends of each yellow board at a 5-degree angle. These cuts will allow the boards to fit snugly against the armrest and leg components.

- Attach the Supports: Position the yellow boards where the armrests will be and secure them to the seating platform. Use wood glue and 2.5-inch screws for a solid connection.

Reinforce the Back Legs

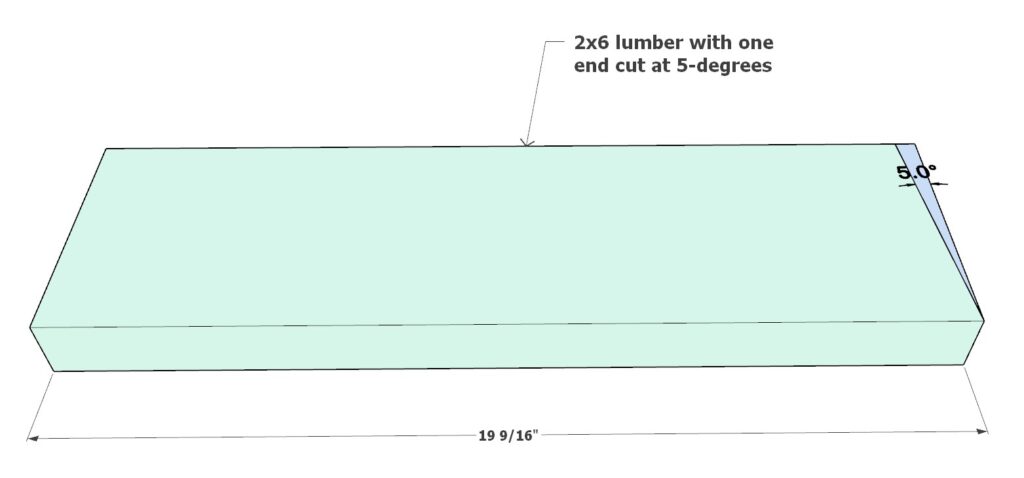

- Prepare the Reinforcement Pieces: Get two pieces of 2×6 lumber, each 19-9/16 inches long. Color-coded in teal.

- Cut the Back Leg Supports: Cut one end of each teal board at a 5-degree angle. This angle will match the incline of the back legs.

- Secure the Back Leg Supports: Apply wood glue to the teal boards, align them with the back legs, and fasten them using 3.5-inch screws. This step adds extra stability to the back legs.

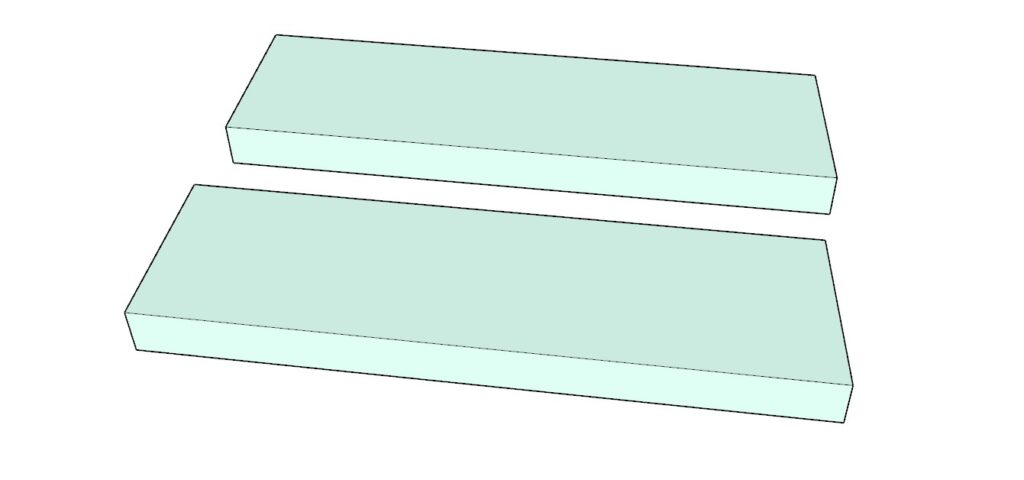

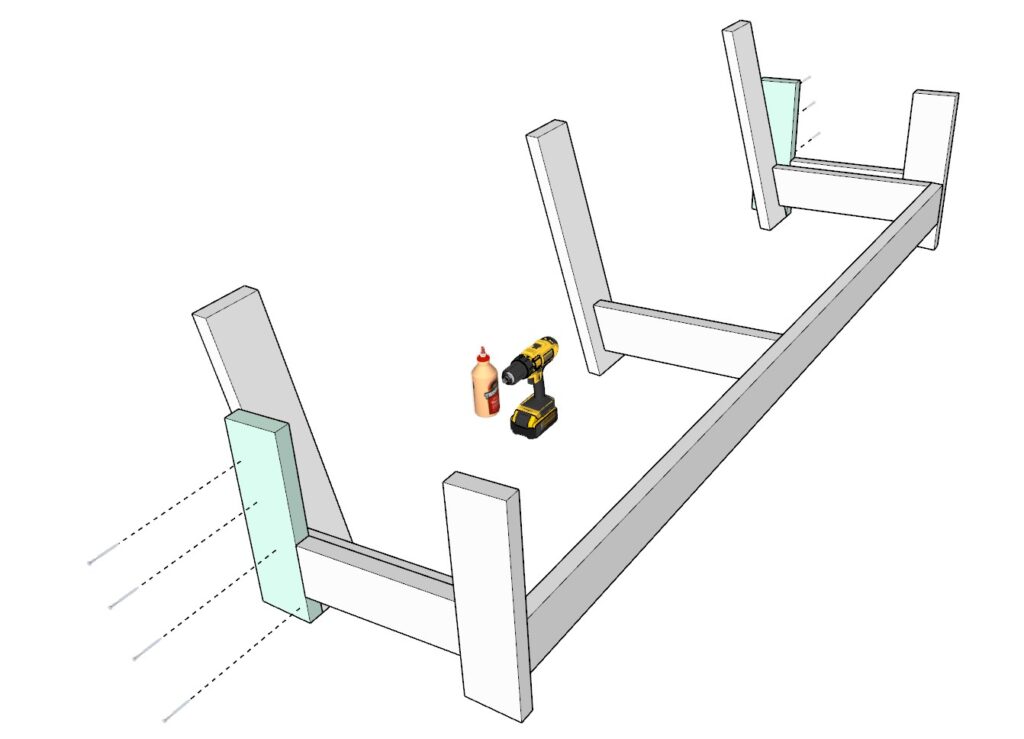

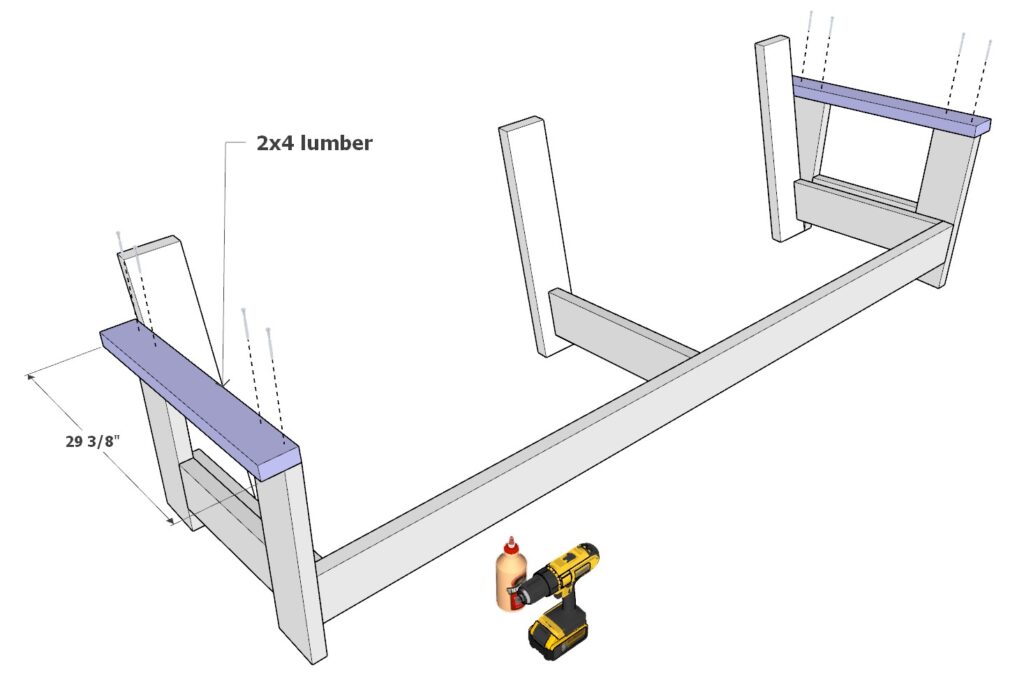

Install the Arm Rests

- Prepare the Arm Rests: Find two pieces of 2×4 lumber, each 29-3/8 inches long, and color-coded purple.

- Attach the Arm Rests: Place the purple boards on top of the armrest supports you’ve just installed. Make sure they’re aligned properly before securing them with 3.5-inch screws and wood glue.

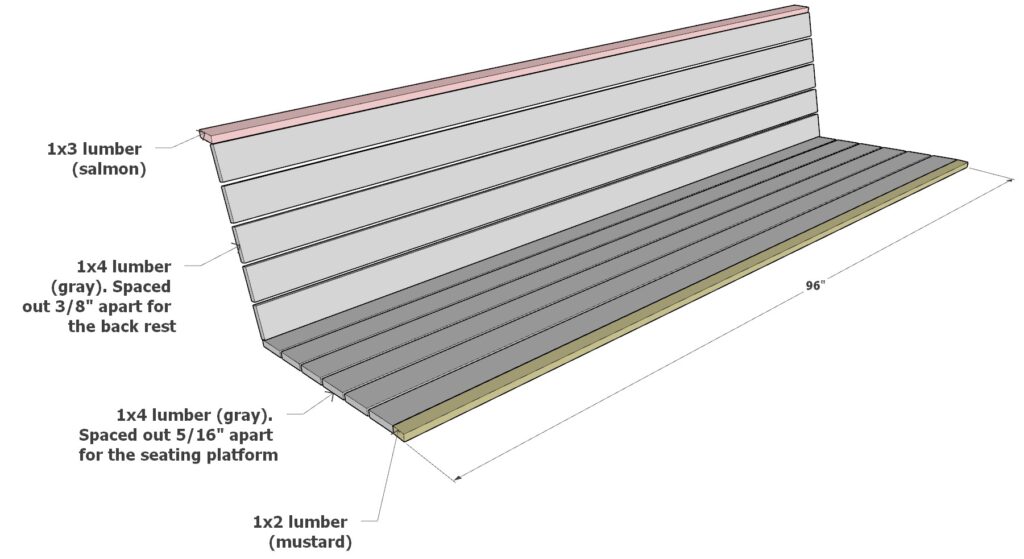

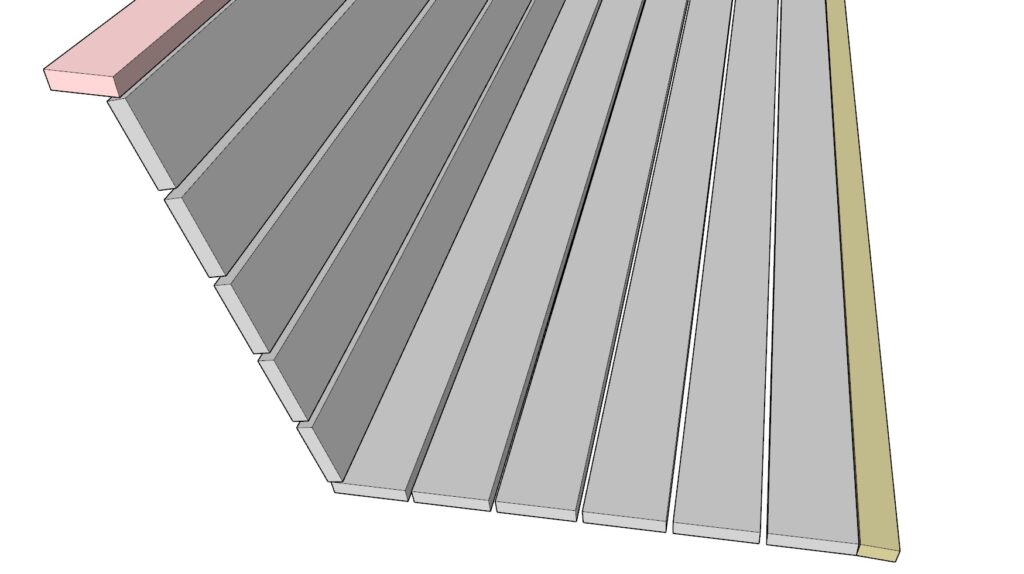

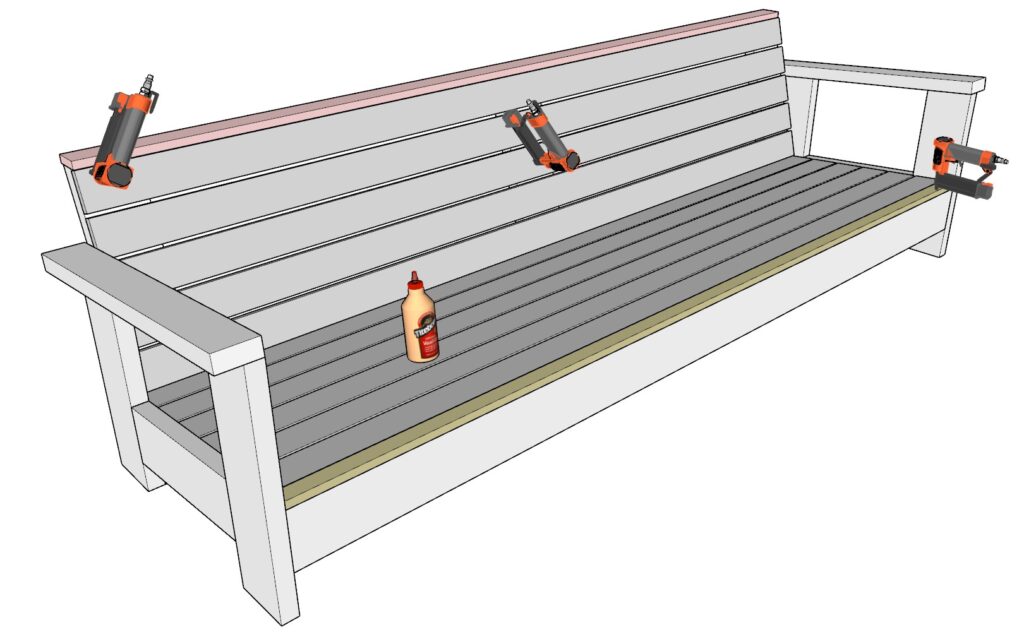

Step 3: Decking the Bench Frame

Attaching the Back Rest Decking

- Prepare the Decking Pieces: Gather five 96-inch 1×4 lumber pieces for the back rest. Color-coded gray.

- Position the Decking: Lay the gray decking pieces across the back rest frame, ensuring they are spaced 3/8-inch apart for a consistent look.

- Secure the Decking: Affix each decking piece with wood glue and 1.5-inch long pin nails for a secure and neat finish.

Decking the Seating Platform

- Prepare the Seat Decking Pieces: Collect six 96-inch 1×4 lumber pieces for the seating platform, also color-coded in gray.

- Space the Decking Evenly: Place these pieces onto the seating platform frame, spacing them 5/16 inches apart to allow for wood movement and drainage.

- Fasten the Decking: Attach the decking to the frame using wood glue and pin nails, ensuring each board is firmly in place.

Adding the Front Lip and Back Topper

- Prepare the Front Lip and Back Topper: Take one 96-inch 1×2 lumber piece for the front lip (color-coded mustard) and one 96-inch 1×3 lumber piece for the top of the back rest (color-coded salmon).

- Install the Front Lip: Attach the mustard-colored piece to the front edge of the seating platform, using pin nails and wood glue.

- Install the Back Topper: Secure the salmon-colored piece to the top of the back rest, providing a polished finish to the edge.

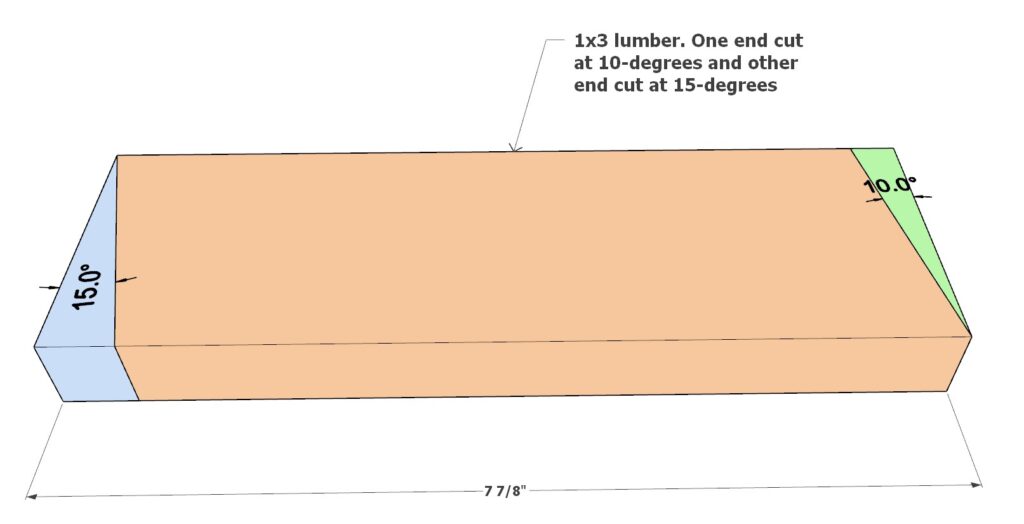

Installing the Side Decorative Pieces

- Prepare the Decorative Pieces: Find two 7-7/8-inch long 1×3 lumber pieces (color-coded orange) for the sides.

- Cut the Angles: Cut one end of each orange piece at a 15-degree angle and the other end at a 10-degree angle to fit snugly against the back rest.

- Attach the Decorative Pieces: Position these pieces on the sides where the back rest decking ends. Secure them with pin nails and wood glue for a seamless look.

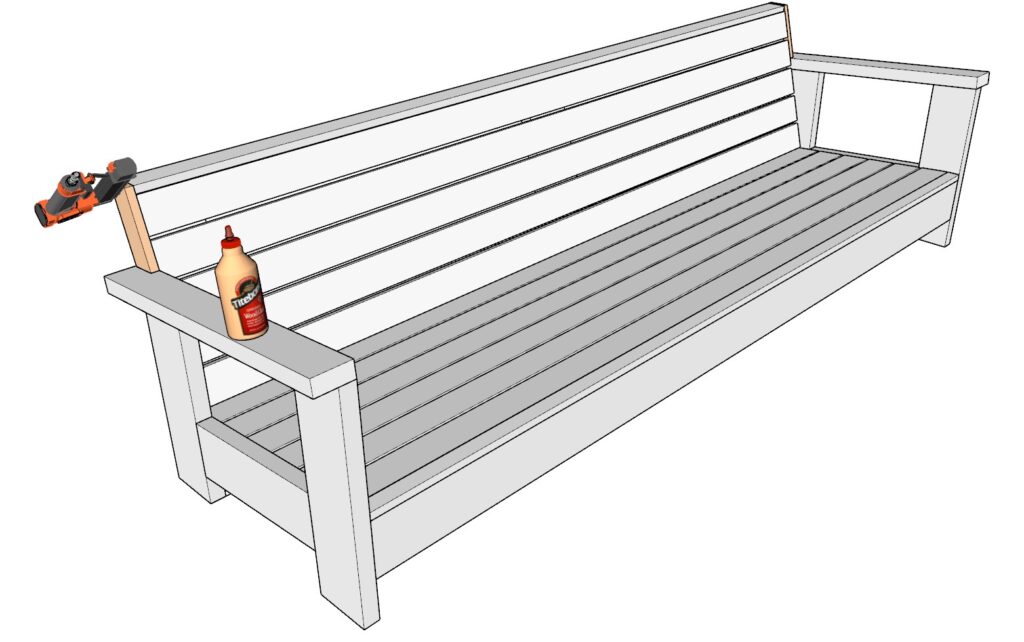

Step 4: Preparing and Finishing Your Bench for Staining or Painting

Preparing for Dowels and Finishing

Inserting Dowels: If you’ve predrilled holes for dowels during the building process, now’s the time to glue them in. Apply a small amount of wood glue to the inside of each hole and to the dowel. Gently tap the dowel into the hole with a hammer until it sits flush with the wood surface. Wipe away any excess glue immediately.

Sanding the Dowels: Once the glue is dry, sand the dowel flush with the wood surface. Begin with a coarse grit sandpaper and finish with a fine grit to ensure a smooth, even surface.

Why Not Wood Putty?: Wood putty is often used to fill screw holes and imperfections. However, it doesn’t stain as well as the surrounding wood and may stand out on the finished bench, making it less ideal unless you’re aiming for a more rustic, natural look.

Staining Your Bench

Choosing Your Stain: Select a wood stain that complements your outdoor space and personal style. Consider using a stain with built-in weather protection for outdoor furniture.

Sanding Before Staining: Sand the entire bench with fine-grit sandpaper to prep the surface. This will help the stain absorb evenly.

Applying the Stain: Use a natural bristle brush or a clean rag to apply the stain. Work in sections, following the wood grain. Apply the stain liberally, and then wipe away any excess after a few minutes, as per the stain’s instructions.

Drying Time: Allow the stain to dry completely, following the manufacturer’s recommended drying time. This may vary based on climate and humidity.

Painting Your Bench

Priming the Wood: If you decide to paint your bench, start with a coat of high-quality outdoor primer. This will help the paint adhere better and last longer.

Sanding Between Coats: After the primer dries, sand lightly with fine-grit sandpaper for a smooth base before painting.

Applying Paint: Choose an exterior paint suitable for wood and your climate. Apply using a brush or roller, working in thin, even coats. Allow the paint to dry between coats.

Top Coat for Protection: For additional protection, especially in harsh weather, apply a clear polyurethane topcoat after the paint has dried.

Maintaining Your Bench

Protection from Elements: Cover your bench during the winter and rainy seasons to protect it from water damage and freezing temperatures.

Shading: If possible, place your bench in a shaded area to prevent excessive sun exposure, which can fade and damage the wood and finish over time.

Re-staining: To re-stain your bench, you’ll need to strip the old stain with a wood stripper, sand the wood, and then apply a new coat of stain.

Re-painting: For repainting, sand the bench to remove the old paint, prime it, and then apply a new coat of paint as you did the first time.

Regular Maintenance: Clean your bench regularly and apply a fresh coat of polyurethane once a year to keep it looking new and to prolong its lifespan.

Tools and Materials (Table):

Available with the purchase of the DIY plan PDF.

Lumber Shopping & Cut List (Table):

Available with the purchase of the DIY plan PDF.

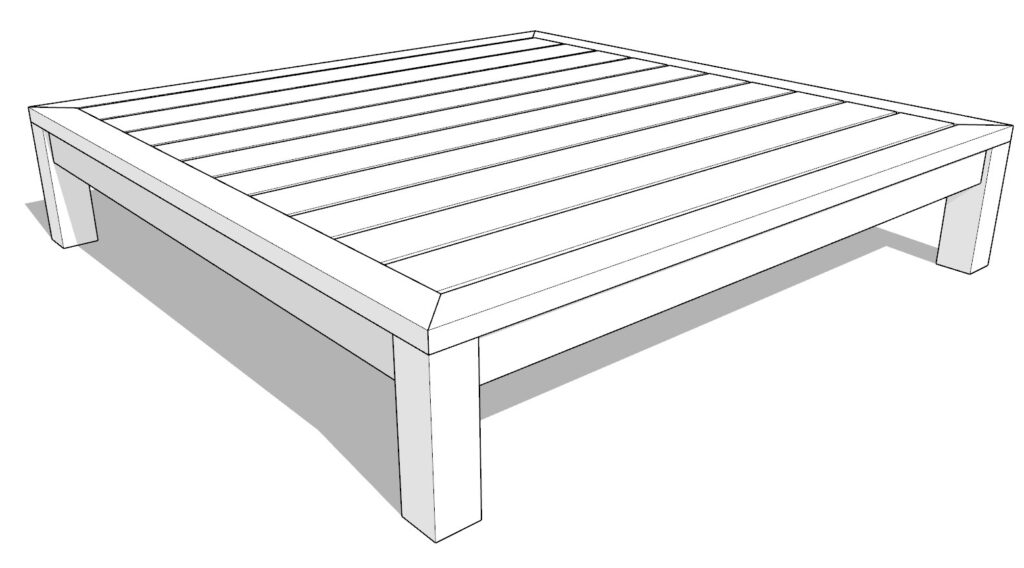

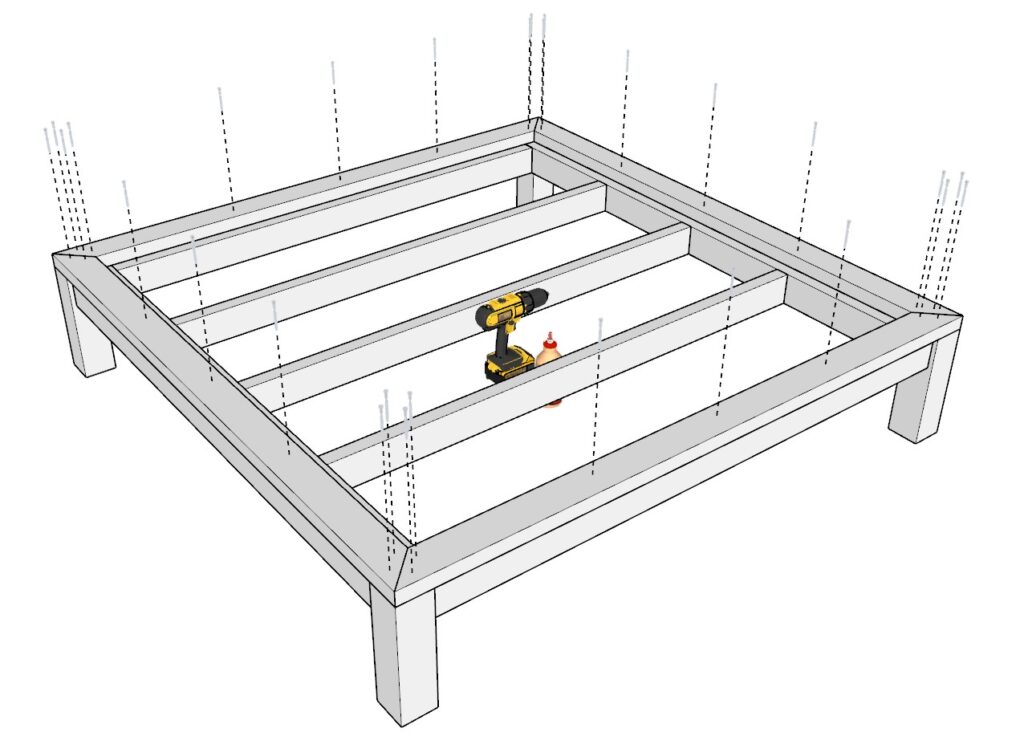

Step 1: Constructing the Table Frame

Building the First Layer

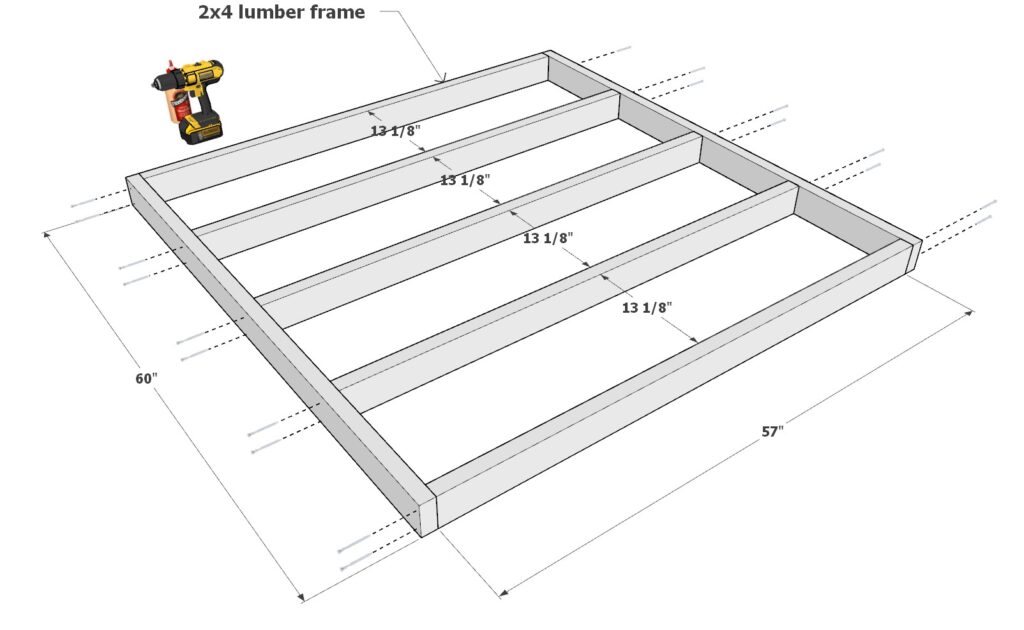

- Prepare the Frame Pieces: Start with two pieces of 2×4 lumber, each cut to 60 inches, and five pieces of 2×4 lumber, each cut to 57 inches.

- Assemble the Frame: Lay out these pieces as shown in the diagram, with the 60-inch pieces serving as the longer sides and the 57-inch pieces spaced evenly in between.

- Secure the Frame: Fasten the pieces together using 3.5-inch screws and wood glue. Ensure all corners are square and the frame is even.

Adding the Second Layer

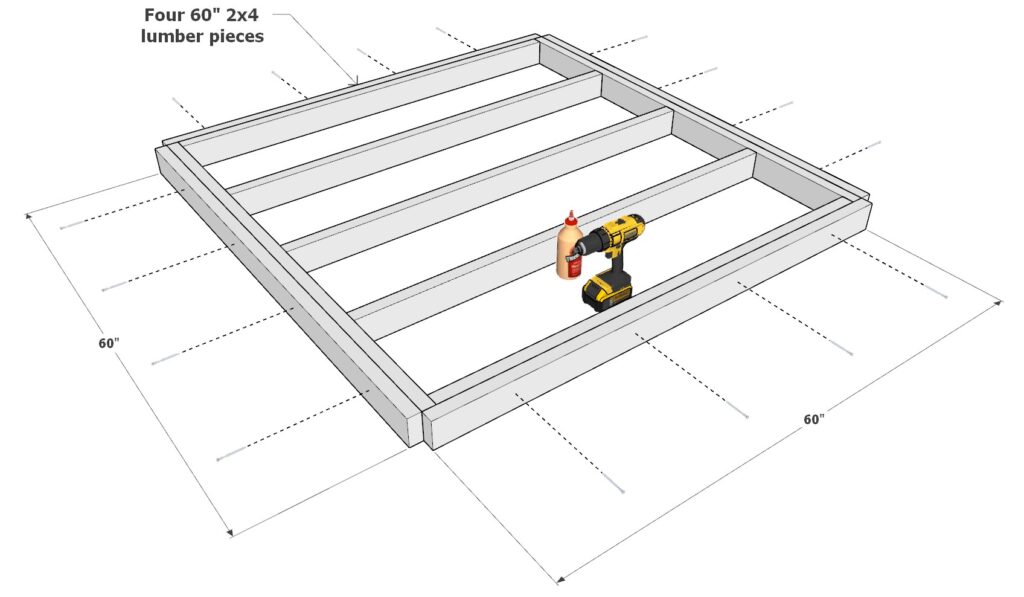

- Prepare the Second Layer Pieces: Cut four pieces of 2×4 lumber, each 60 inches long, for the second layer of the frame.

- Attach the Second Layer: Place these four pieces on top of the first layer frame. Align them so that they sit flush with the edges.

- Secure the Second Layer: Use 2.5-inch screws and wood glue to attach this layer to the first. The shorter screws ensure they don’t protrude through the surface.

Completing with the Third Layer

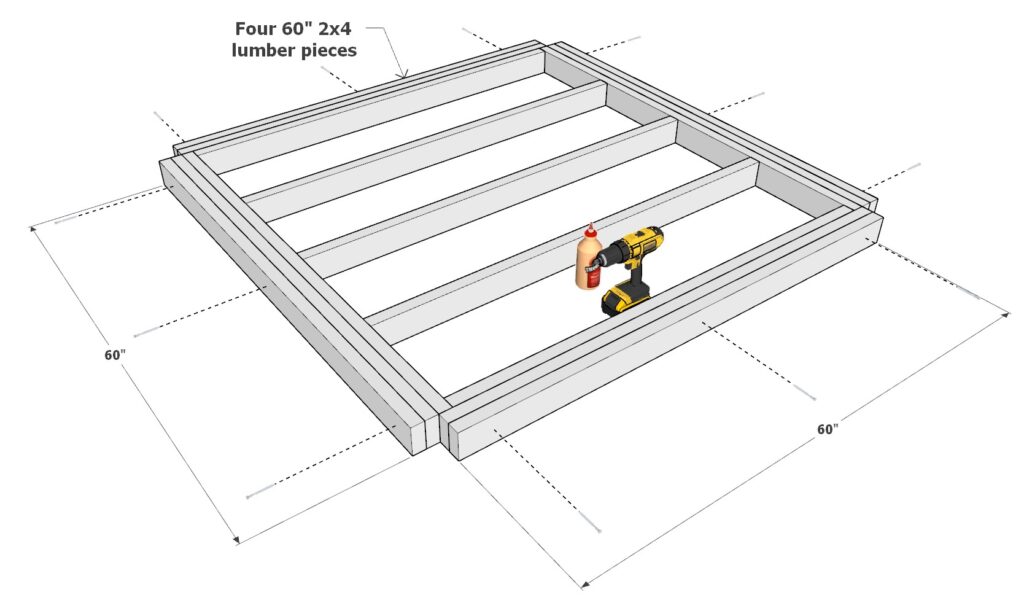

- Prepare the Third Layer Pieces: Cut another four pieces of 2×4 lumber, each 60 inches long, for the top layer of the frame.

- Adding the Final Layer: Arrange these pieces on top of the second layer, aligning them as before.

- Securing the Top Layer: Fasten these with 3.5-inch screws. If you plan to use dowels for a cleaner finish, predrill holes for the dowels at this stage.

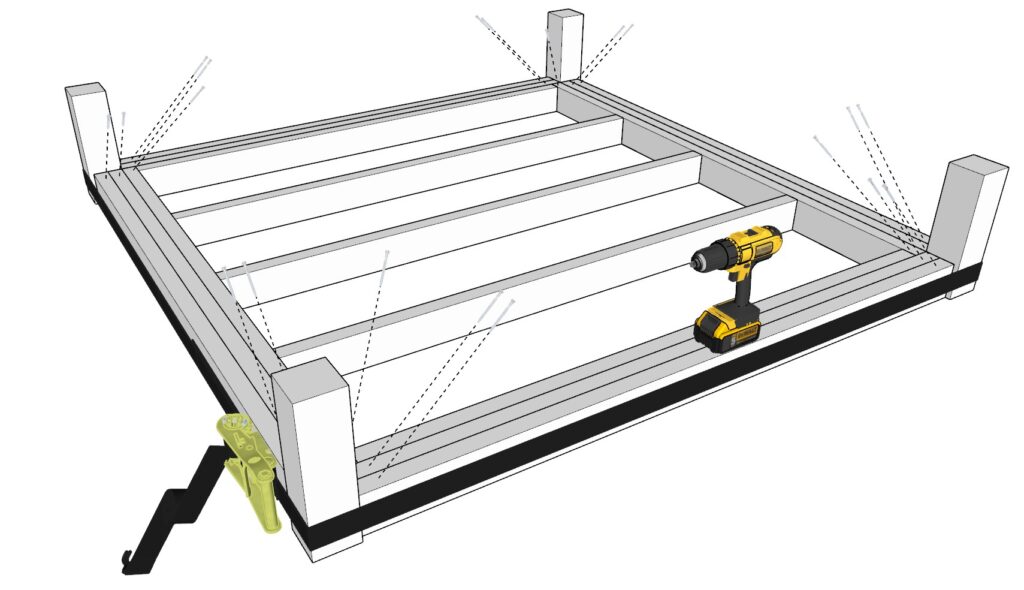

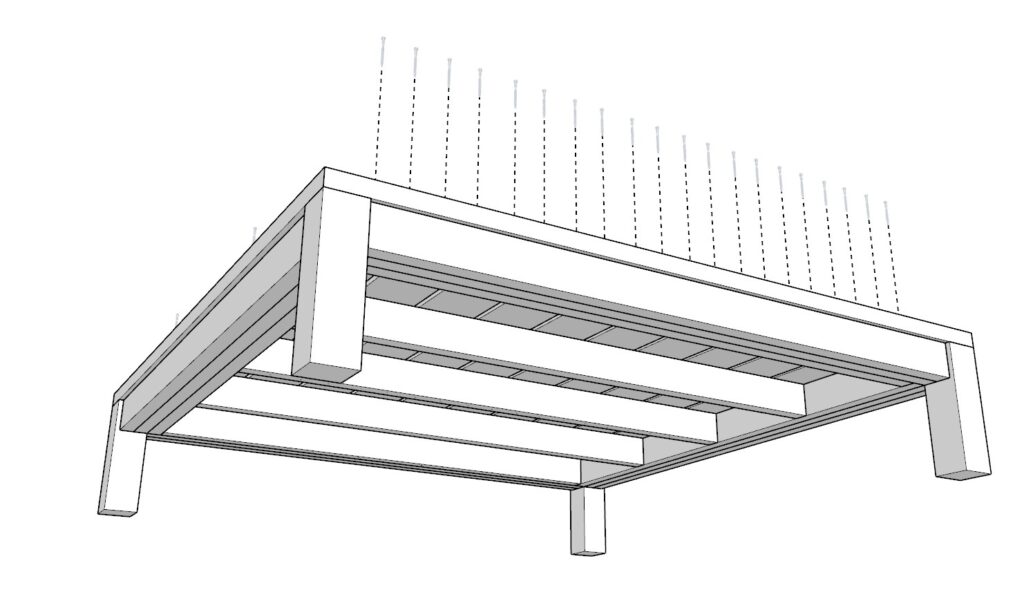

Step 2: Attaching the Table Legs

Preparing the Legs

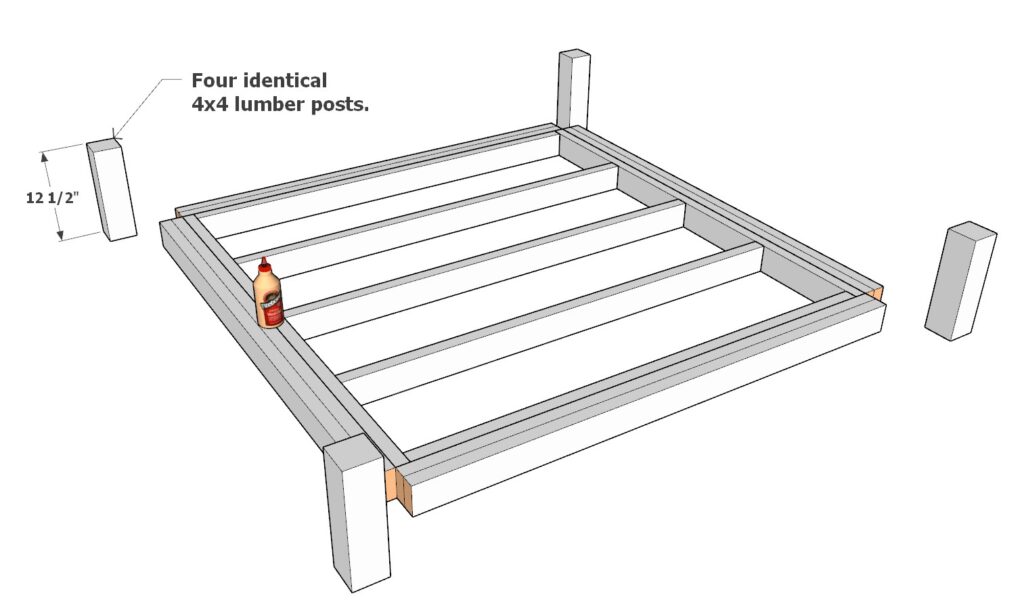

- Cut the Legs: Prepare four pieces of 4×4 lumber, each 12-1/2 inches tall.

Gluing and Securing the Legs

- Apply Wood Glue: Generously apply wood glue to the areas of the frame where the 4×4 legs will be attached.

- Position the Legs: Place the legs in their respective positions, ensuring they are flush and level with the frame. Use a level surface for accurate alignment.

- Secure with Ratchet Straps: Wrap a ratchet strap around the entire frame and legs. If one strap isn’t long enough, connect two straps. Initially, tighten the strap snugly but not excessively, allowing for adjustments.

- Adjusting for Precision: Check all leg positions, ensuring they are correctly placed and flush with the frame. Gently tap any stubborn parts with a wood hammer to adjust.

- Final Tightening: Once everything is aligned, tighten the ratchet straps firmly to hold the legs in place securely. Nothing should move.

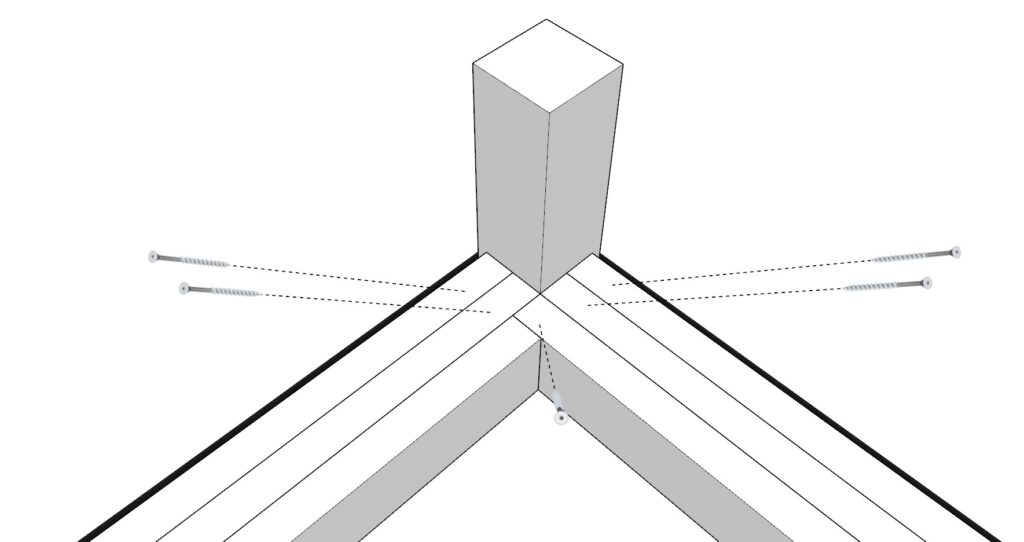

- Adding Screws for Stability: Drill and drive 3.5-inch screws diagonally into the legs and frame as indicated in the diagram. This will add extra stability to the joints.

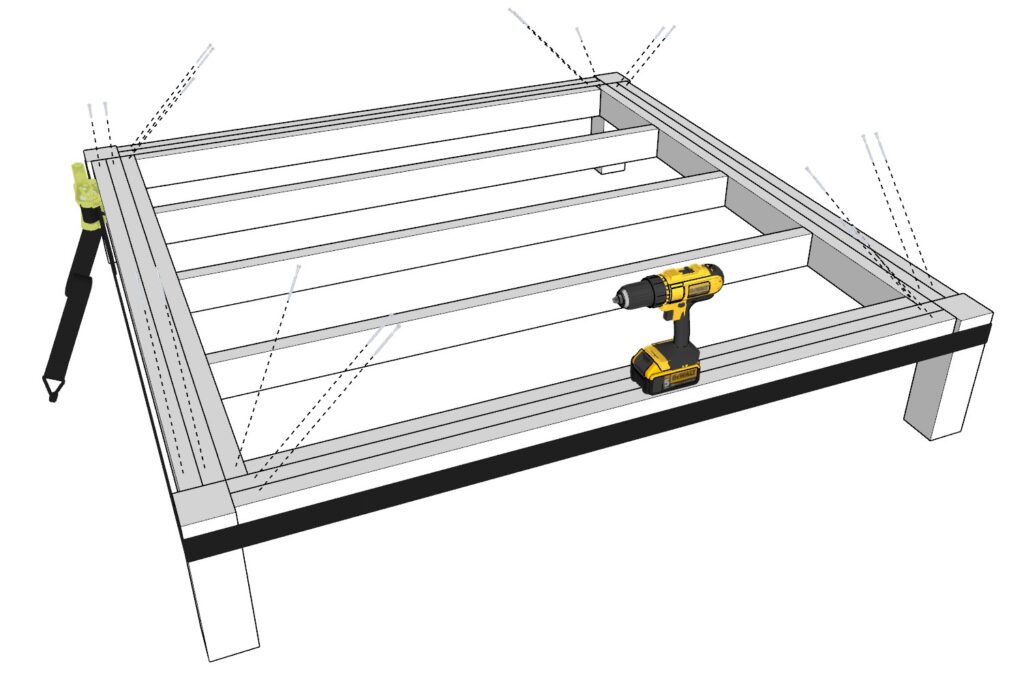

Flipping the Table

- Assistance Required: Get help to flip the table over. It’s important to do this carefully to avoid putting undue pressure on the legs while the glue is still drying. Flip mid-air.

- Additional Screwing: Once flipped, add additional 3.5-inch screws as shown in the diagram to further secure the legs.

Handy Tips:

- Pre-Drilling Is Crucial: Always pre-drill before inserting screws to prevent the wood from splitting. Use an old drill bit, as it might get damaged due to possible screw collisions.

- Patience with Glue: Allow sufficient time for the glue to dry before putting any weight on the table or using it.

- Consistency in Tightening: Ensure the ratchet straps are evenly tightened around the frame to maintain uniform pressure.

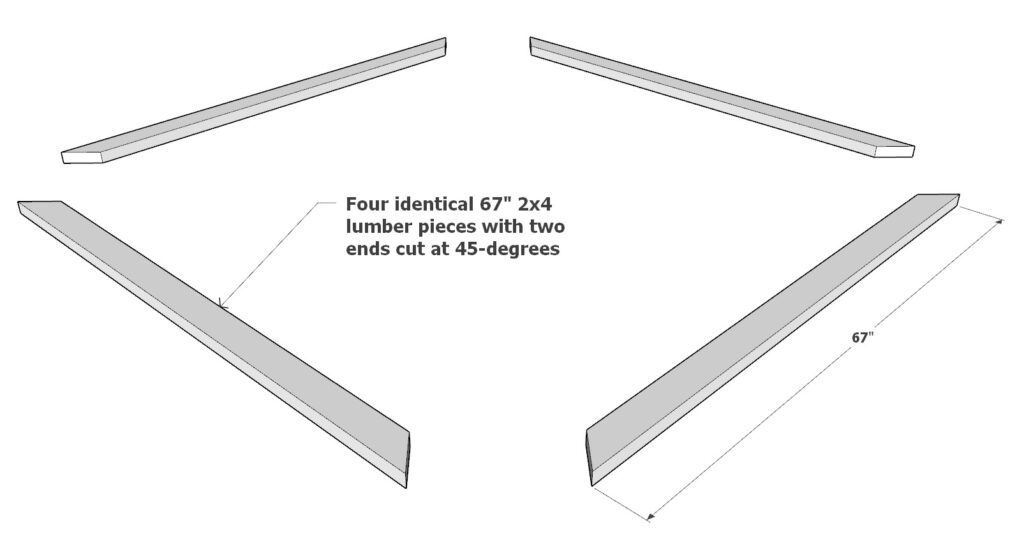

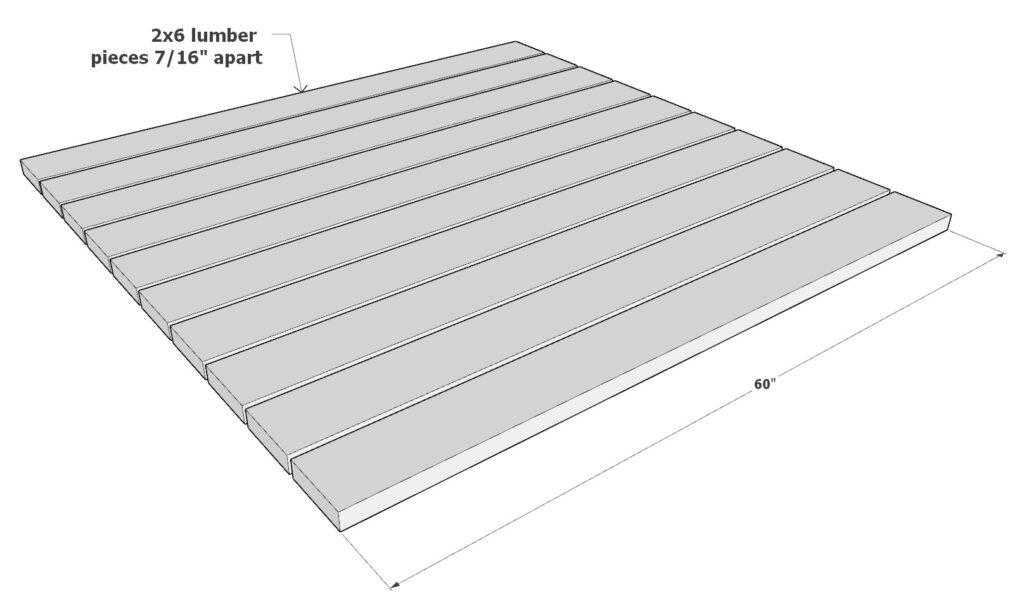

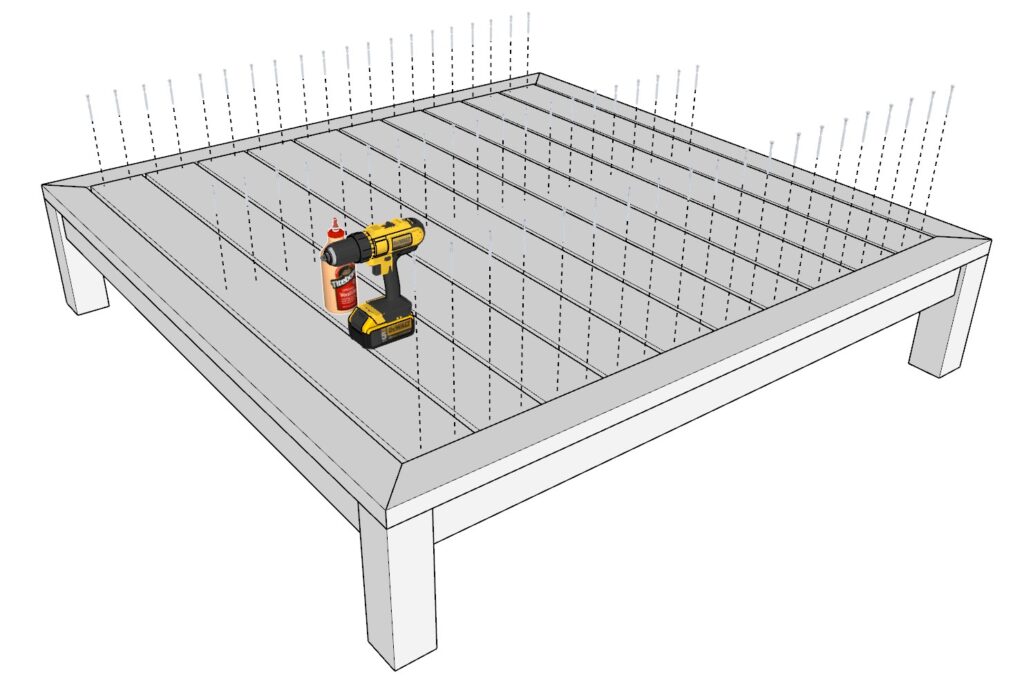

Step 3: Adding the Table Top

Creating the Table Top Perimeter

- Prepare the Perimeter Boards: Cut four 2×4 lumber boards to 67 inches each. Both ends of each board should be cut at a 45-degree angle.

- Assemble the Perimeter: Arrange these boards to form the perimeter of the table top. The angled cuts will help the corners meet neatly.

- Securing the Perimeter: Use wood glue and 3.5-inch screws to attach the boards together. If you’re planning to use dowels for a cleaner finish, predrill the holes with a Forstner bit before inserting the screws.

Adding the Table Top Boards

- Prepare the Top Boards: Take ten 2×6 lumber pieces, each cut to 60 inches.

- Spacing the Boards: Lay these boards across the table frame within the perimeter you’ve created, spacing them 7/16 inches apart. This spacing allows for wood expansion and drainage.

- Securing the Top Boards: Attach each board to the frame using wood glue and 3.5-inch screws. Ensure to predrill holes if you are planning to insert dowels later.

Handy Tips:

- Ensuring Even Spacing: Use a spacer or a ruler to maintain consistent spacing between the top boards.

- Predrilling for Dowels: When predrilling for dowels, make sure the holes align properly with the frame beneath to ensure a tight and clean fit.

- Glue Application: Apply glue evenly but avoid excessive amounts that could squeeze out and create a mess.

- Final Check for Alignment: Once all the boards are secured, do a final check to make sure everything is aligned and level before the glue sets.

Step 4: Preparing and Finishing the Table for Staining or Painting

Adding Dowels and Rounding Edges

Inserting Dowels: If you’ve predrilled holes for dowels during construction, now’s the time to insert them. Apply wood glue to each hole and to the dowel. Gently tap the dowel into the hole until it’s flush with the surface. Allow the glue to dry completely before proceeding.

Rounding Off Edges: Use a router with a rounding-over bit to smooth the edges of the table. If you don’t have a router, you can achieve a similar effect by hand-sanding the edges. This not only adds a finished look but also makes the table safer by eliminating sharp edges.

Dowels vs. Wood Putty

Dowels for Staining: Dowels are preferred if you plan to stain your table, as they will take the stain more similarly to the rest of the wood, providing a more uniform appearance.

Wood Putty for Painting: If you’re painting the table, wood putty is a good choice to fill any holes or imperfections. Putty doesn’t stain well but can be easily painted over, making it suitable for painted finishes.

Staining the Table

Sanding Before Staining: Thoroughly sand the entire table with fine-grit sandpaper to prepare it for staining. This ensures the stain applies evenly.

Applying the Stain: Choose an outdoor-appropriate wood stain. Apply it with a brush or rag, working in sections and going along with the wood grain. Wipe off any excess stain after a few minutes, following the stain manufacturer’s instructions.

Painting the Table

Applying Primer: If painting, start by applying an outdoor-grade primer. Let it dry and lightly sand the surface for a smooth base.

Painting: Apply exterior paint suitable for wood. Use a brush or roller to apply thin, even coats. Let each coat dry completely before applying the next.

Maintaining and Refinishing

Regular Maintenance: Clean the table regularly and cover it during harsh weather conditions. If exposed to sunlight, consider placing it in a shaded area to prevent fading.

Re-staining: To re-stain, strip off the old stain, sand the surface, and reapply a new stain coat.

Repainting: For repainting, sand down the old paint, apply a new layer of primer, and then repaint as before.

Protective Coating: Annually apply a coat of protective polyurethane to extend the life of the finish and protect the wood.