Introduction

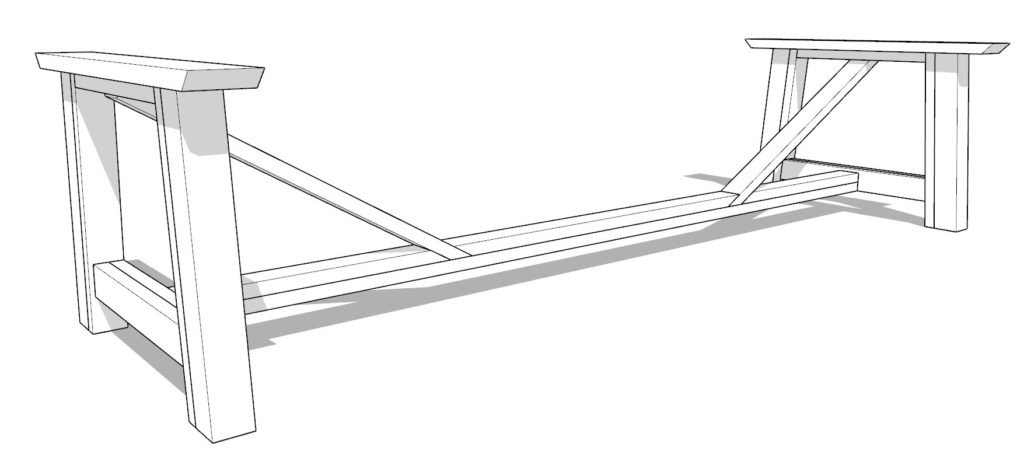

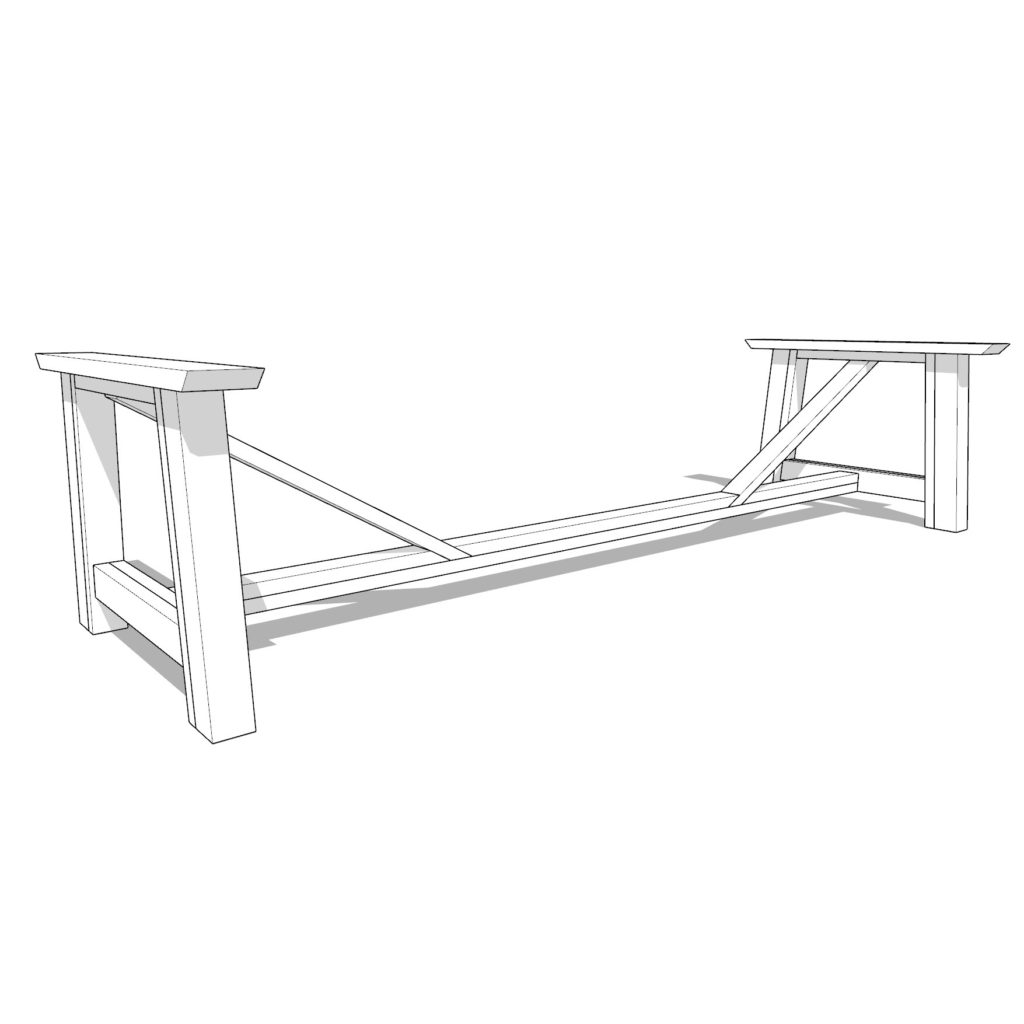

Envision the base of your very own custom table, a foundational piece where design meets durability. This isn’t just any base; it’s the bedrock for where your loved ones will gather, share meals, and create memories. It’s your first step in crafting a piece that captures the essence of your home.

Specifications

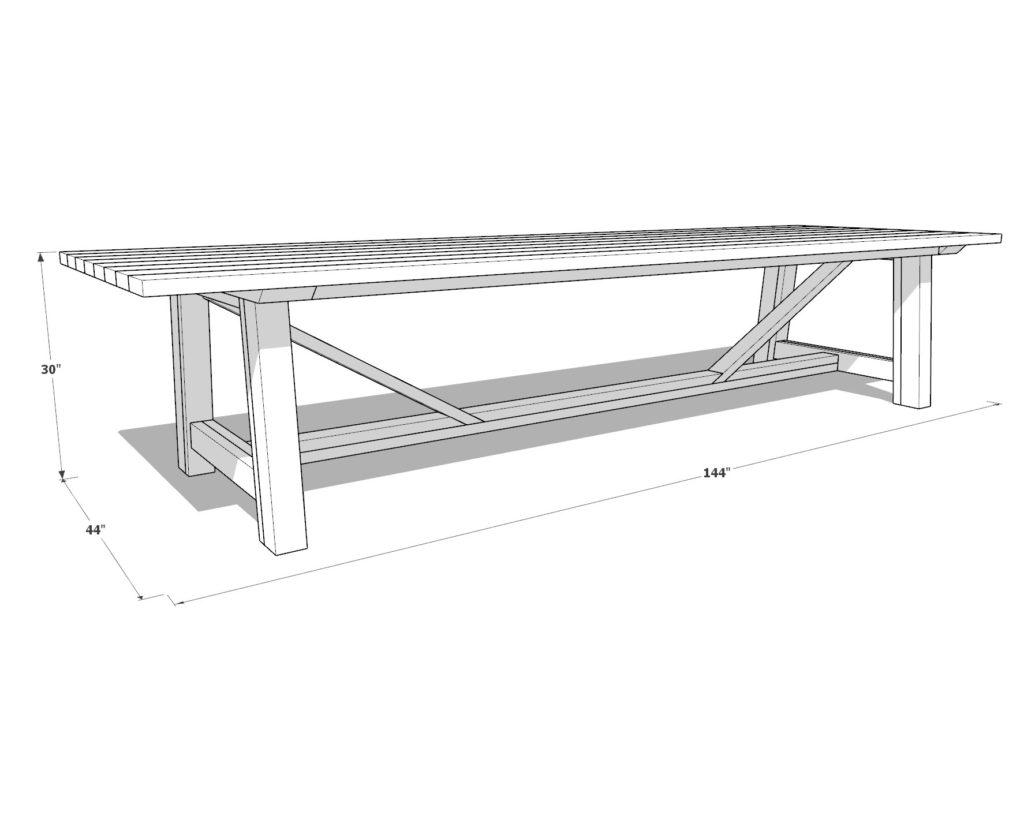

Our robust table base is meticulously engineered to anchor a substantial tabletop, with dimensions that harmonize strength and space. It stands 28-1/2 inches tall, ensuring a comfortable height for seating, while the 44-inch width provides a stable stance for various tabletop designs. At 122 inches in length, it is the perfect underpinning for a 12-foot top, yet the design remains adaptable for custom lengths to accommodate your specific design vision and space requirements. Whether you’re aiming for a cozy kitchen nook or a grand dining hall centerpiece, this base adjusts to your plan with elegance and ease.

This is a Beginner-Friendly Project

Dive into the world of DIY without reservation. This table base plan is crafted with the beginner in mind, offering straightforward instructions for an easy assembly process. We guide you through each step, ensuring you have a solid and stylish base ready for any tabletop you choose.

Customization Options

Match the table base to your style and space requirements. Shorten it for intimate spaces or lengthen it to fill a grand dining room. Select your preferred wood — be it the rustic touch of Cedar or the strength of Douglas Fir — to make a statement that’s authentically yours.

What Makes Our DIY Plan Stand Out

Our DIY table base plan stands out with its clear, easy-to-follow steps, complete with imperial measurements and visual aids for a hassle-free experience. We provide more than just construction steps; we offer tips on how to give your base a finished look that resonates with your personal style, from staining to painting.

Conclusion

Start your DIY journey with a table base that’s more than just the support for a tabletop — it’s a support for a lifetime of stories. With our plan, you’re not just building furniture; you’re crafting an integral part of your home. Seize this opportunity to create a base that will hold not just a tabletop but a wealth of future memories.

Download your table base plan now and begin the exciting process of bringing your vision to life.

Time

6 hours (varies with experience)

Cost

$150 (Costs may vary based on location and supplier.)

Skill level required

Beginner

DIY Table Base PDF Plan

What is included in the PDF download?

- Easy to read step by step instructions

- Material list

- Tools needed

- Helpful links to materials and tools needed

Tools Needed for This Project:

Available with the purchase of the DIY plan PDF.

Lumber Shopping & Cut List

Available with the purchase of the DIY plan PDF.

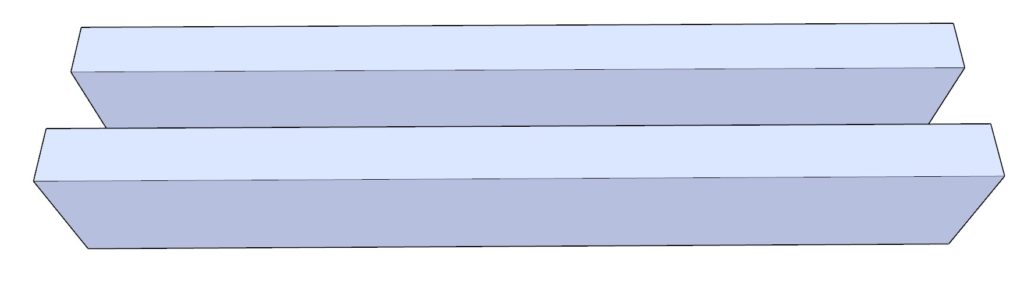

Step 1: Cutting and Assembling the Table Base Frame

Cutting the Pieces:

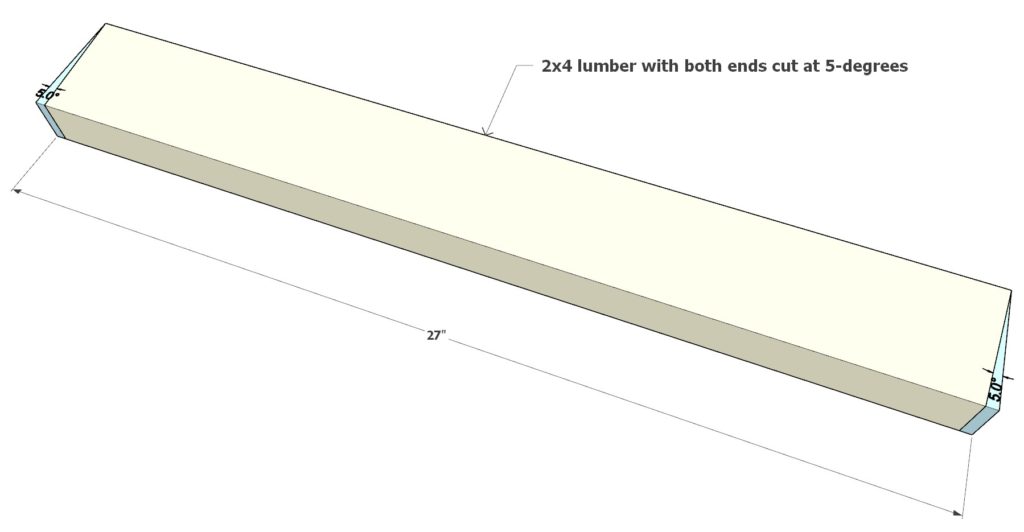

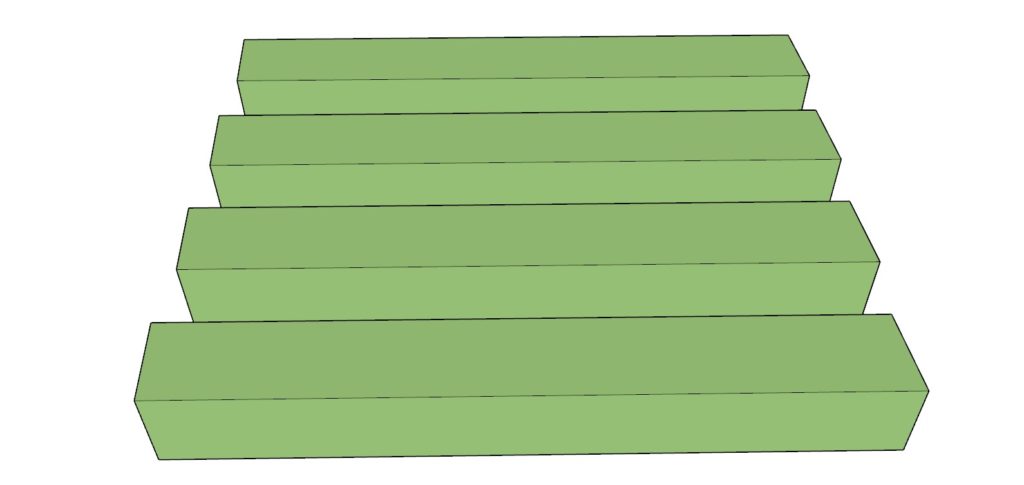

- 27-inch 2x4s: Cut both ends at a 5-degree angle. You’ll need four pieces in pastel yellow.

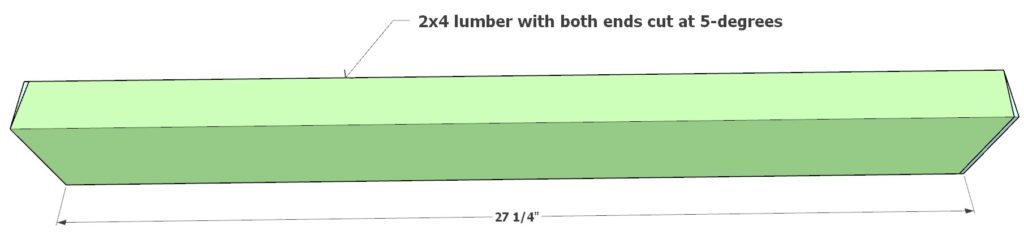

- 27-1/4 inch 2x4s: Cut both ends at a 5-degree angle. You’ll need four pieces in light green.

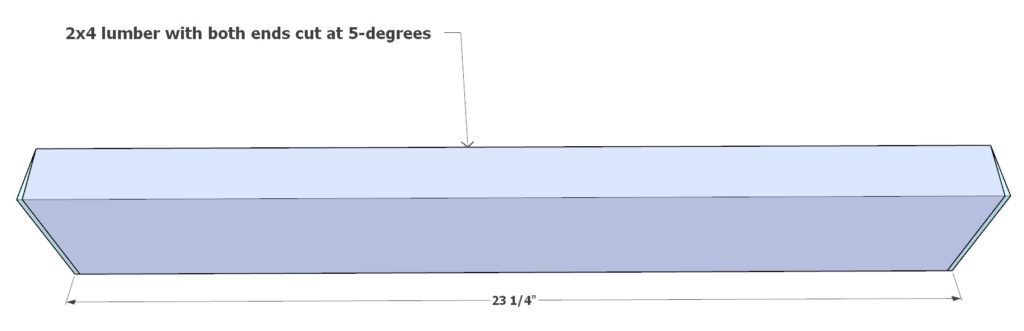

- 23-1/4 inch 2x4s: Cut both ends at a 5-degree angle. You’ll need two pieces in lavender.

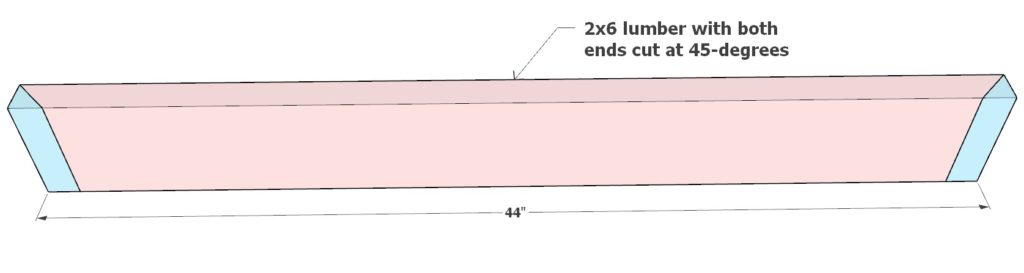

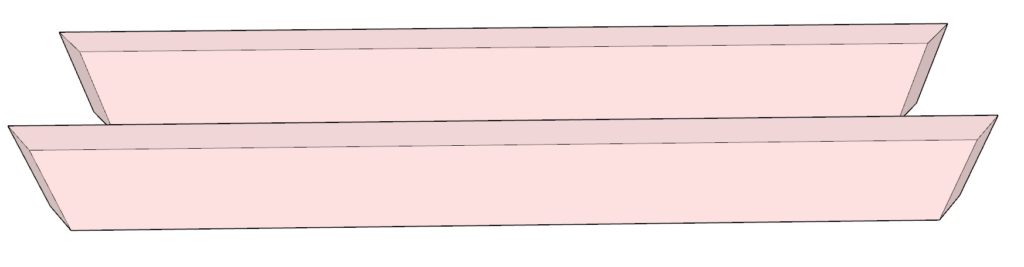

- 44-inch 2x6s: Cut both ends at a 45-degree angle. You’ll need two pieces in pink.

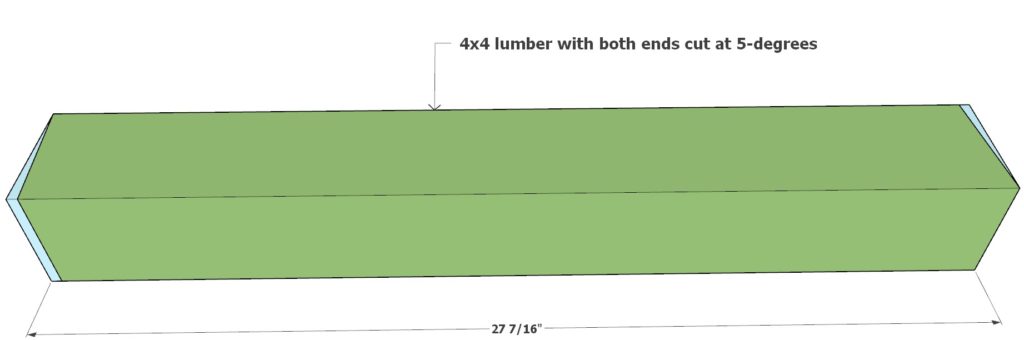

- 27-7/16 inch 4x4s: Cut both ends at a 5-degree angle. You’ll need four pieces in dark green.

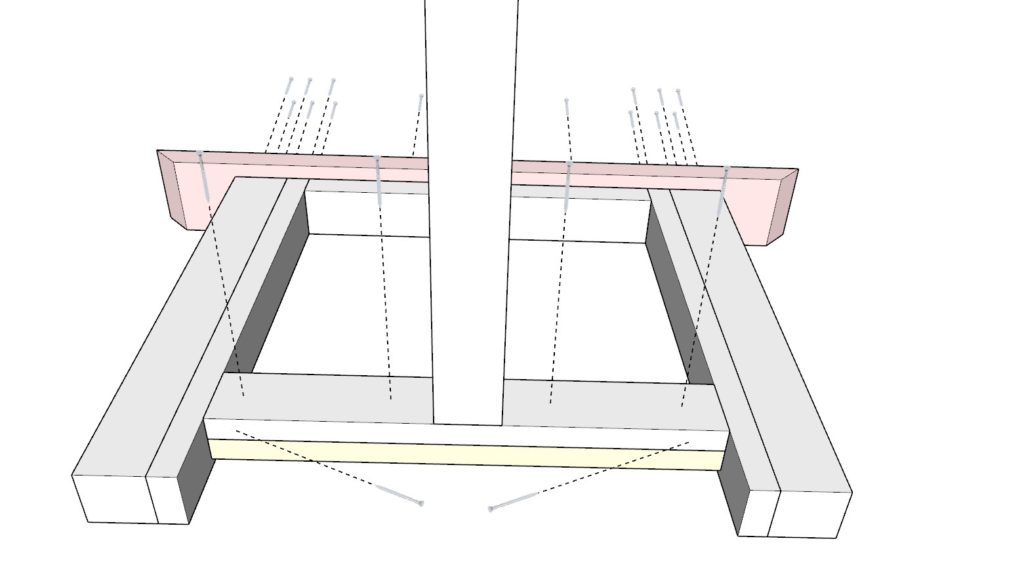

Assembling the A-Frame:

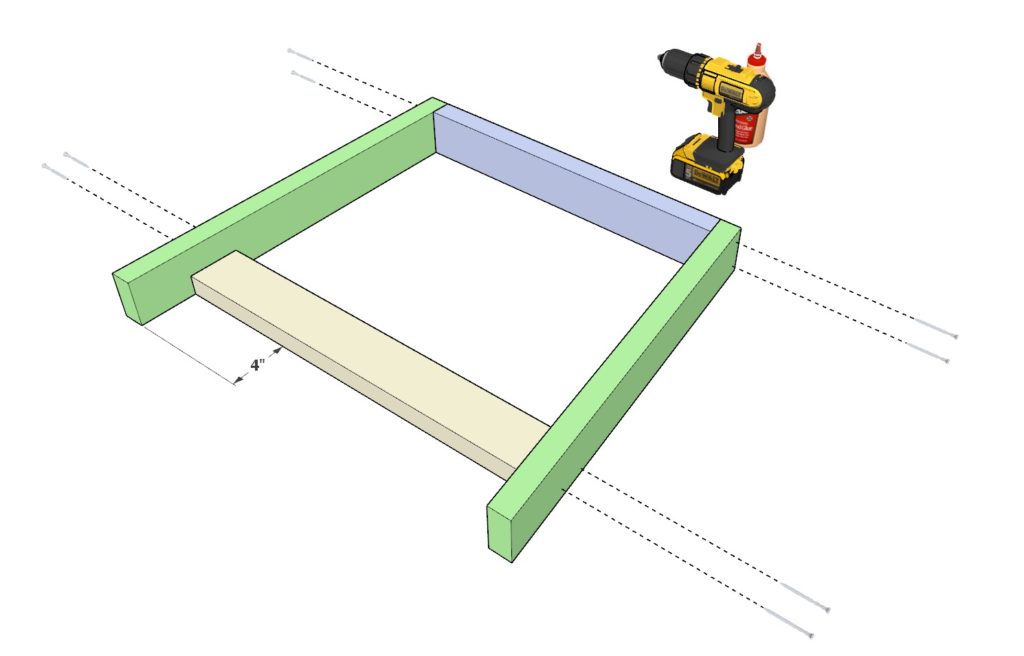

- Start Assembly: Take two light green pieces, one lavender piece, and one pastel yellow piece. Join them using wood glue and 3.5-inch screws.

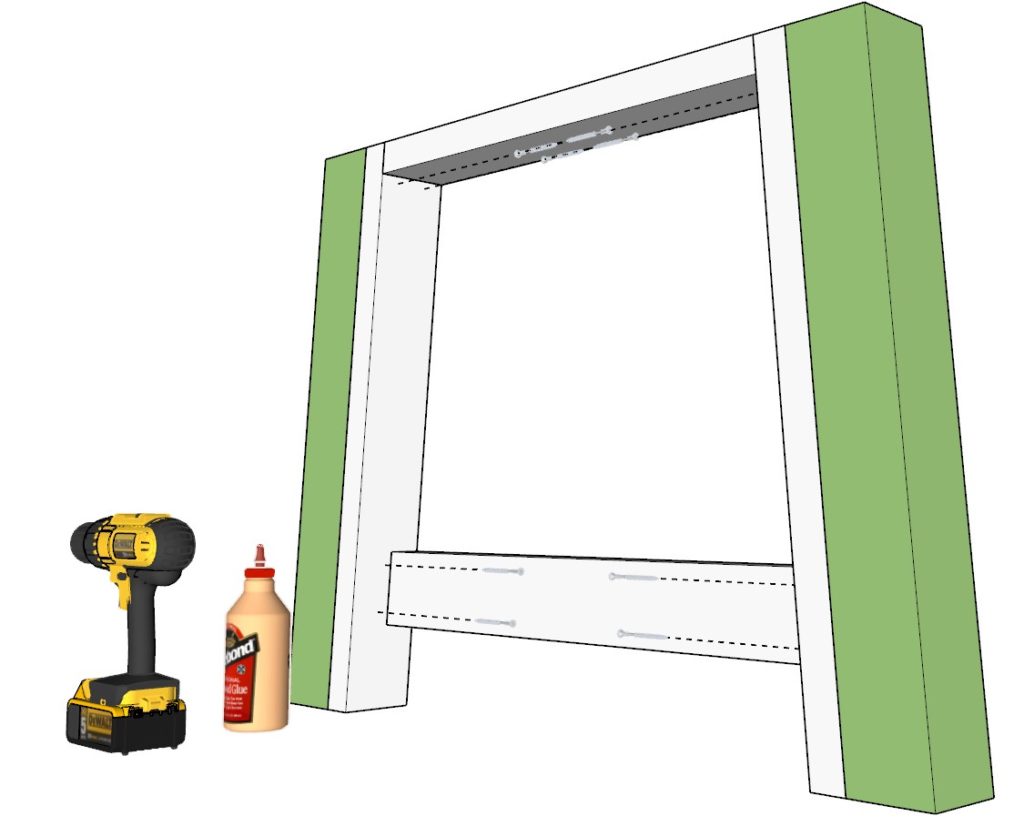

- Attach Vertical Supports: Secure two dark green pieces to the light green pieces using wood glue and 3.5-inch screws.

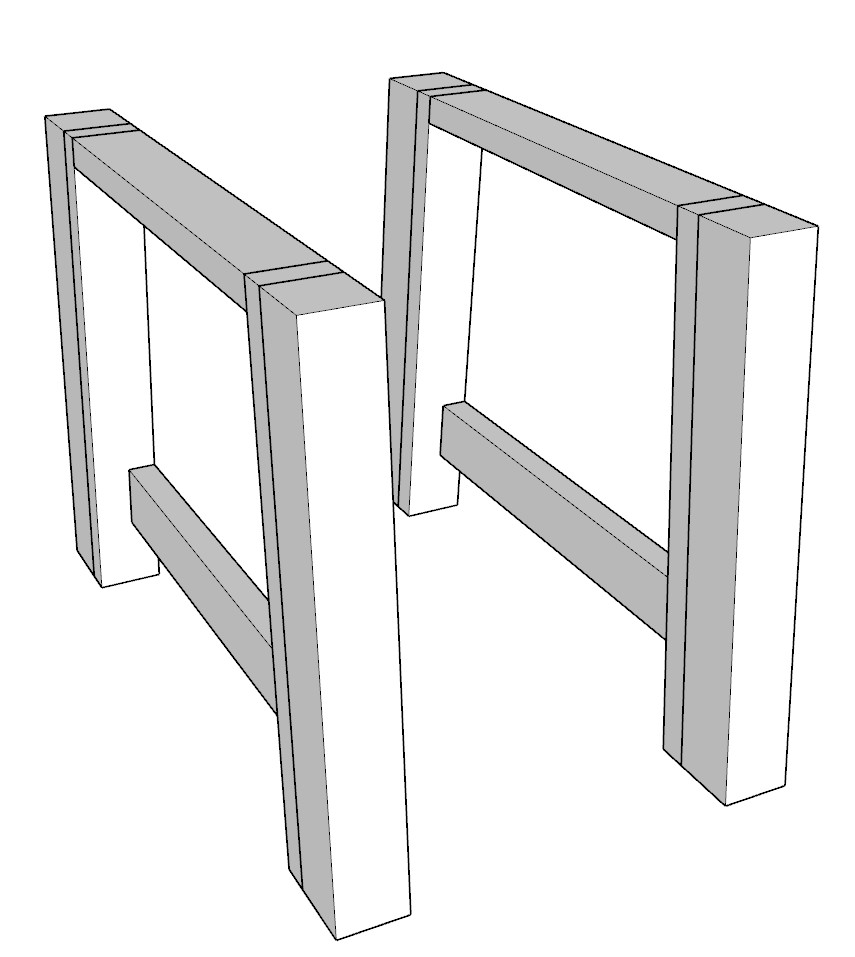

- Create Two A-Frames: Ensure you have two identical A-frame leg assemblies before proceeding.

Tips for a Professional Finish:

- Countersinking: Use a countersink drill bit for screw holes to achieve a neater finish.

- Hole Plugs: If using dowels to plug screw holes, predrill to match the dowel size. For wood putty, note that it may stain differently than wood.

- Pre-Staining: For a more professional look, consider staining or painting pieces before assembly.

- Glue Cleanup: Wipe off any excess glue immediately. Dried glue can affect stain absorption and appearance, especially if staining a dark color over light wood.

Step 2: Constructing the Table Frame Supports

Preparing the Supports:

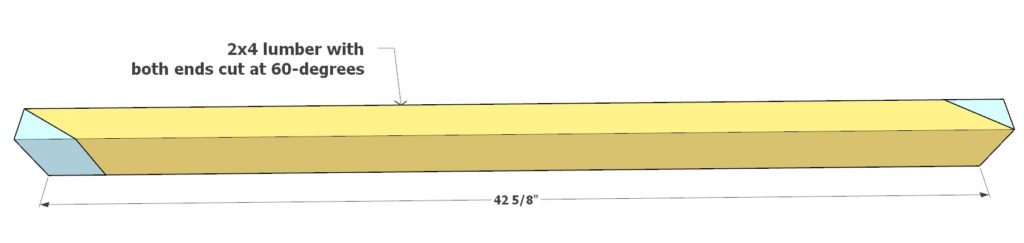

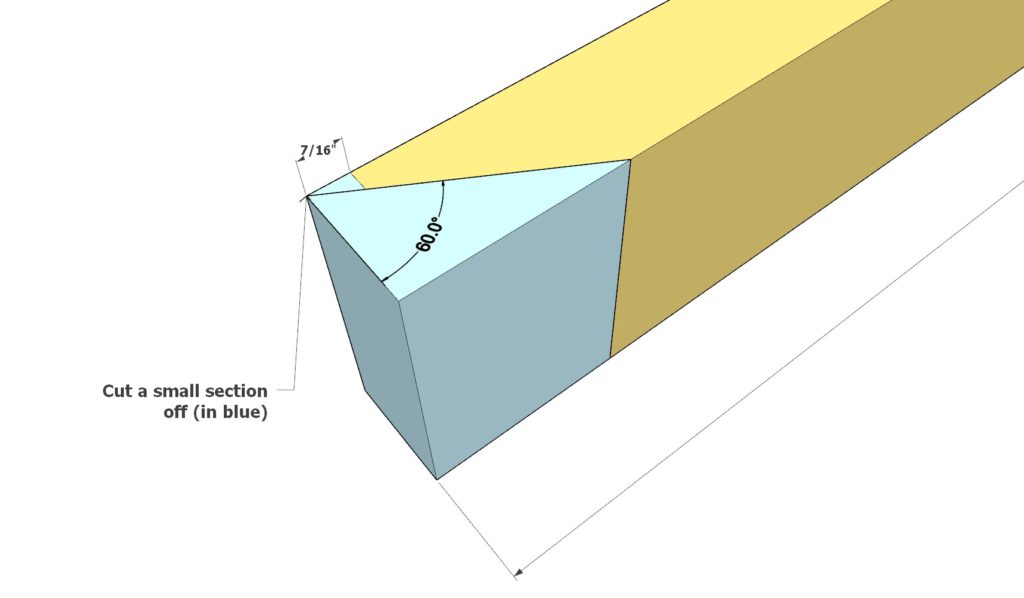

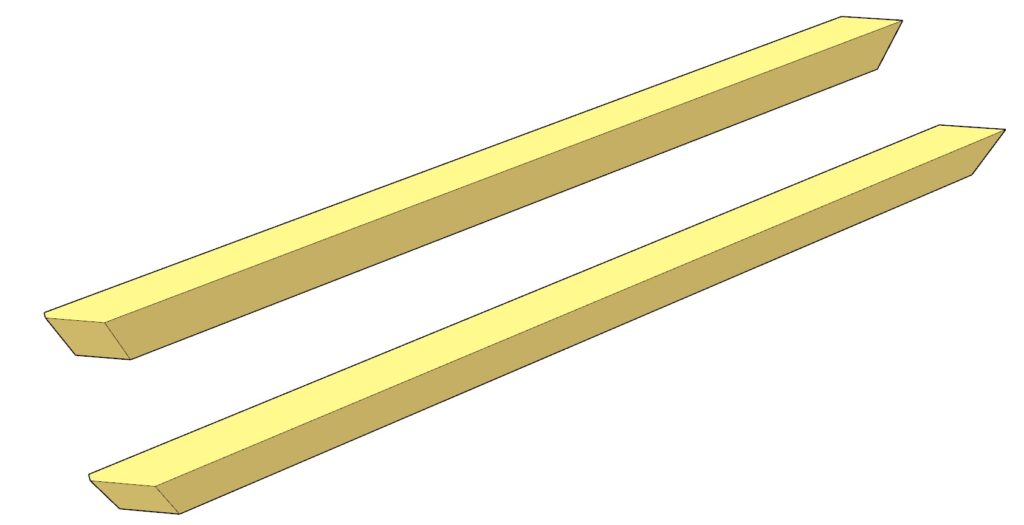

- Long Cross Beams (Bright Yellow): Cut two pieces of 2×4 lumber to 42-5/8 inches with both ends at 60-degrees. Then, as indicated, slightly trim one end of each piece.

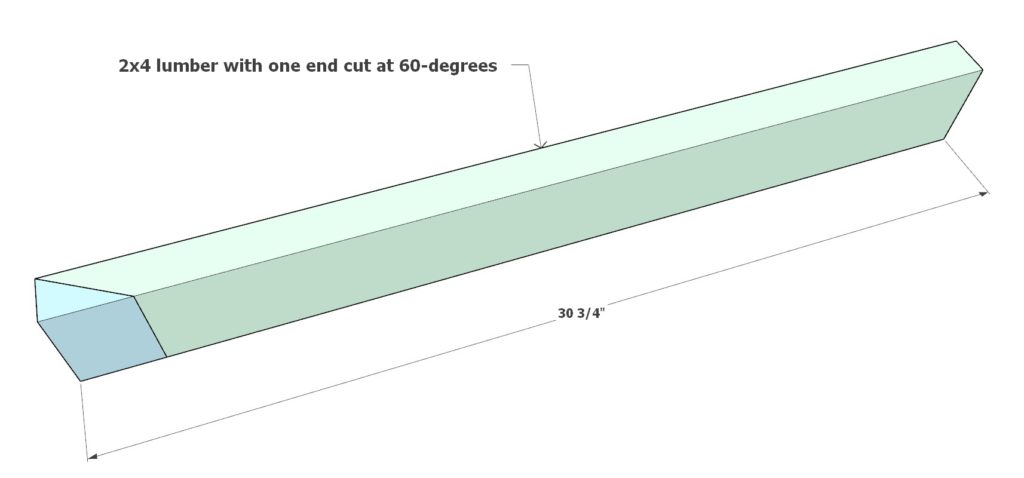

- Short Cross Beams (Teal): Cut two pieces of 2×4 lumber to 30-3/4 inches with one end at 60-degrees.

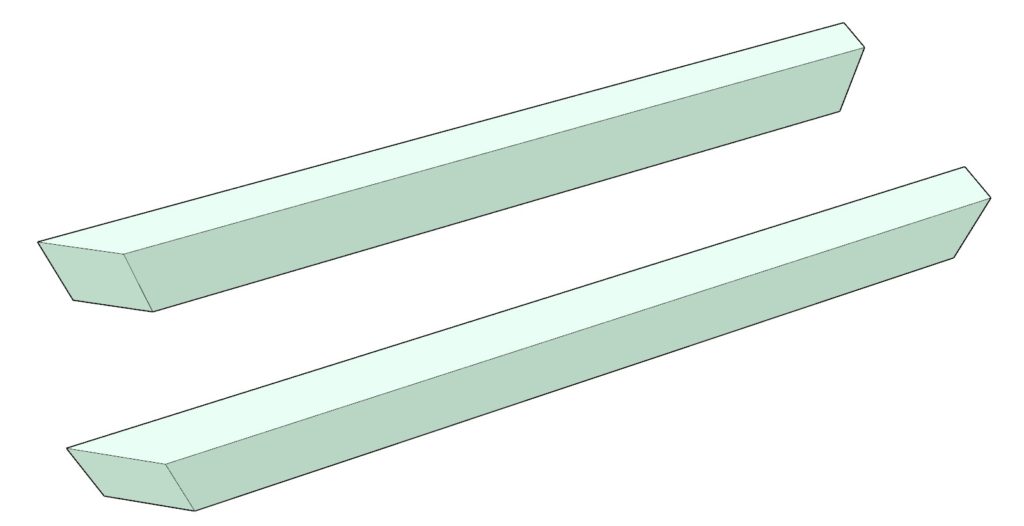

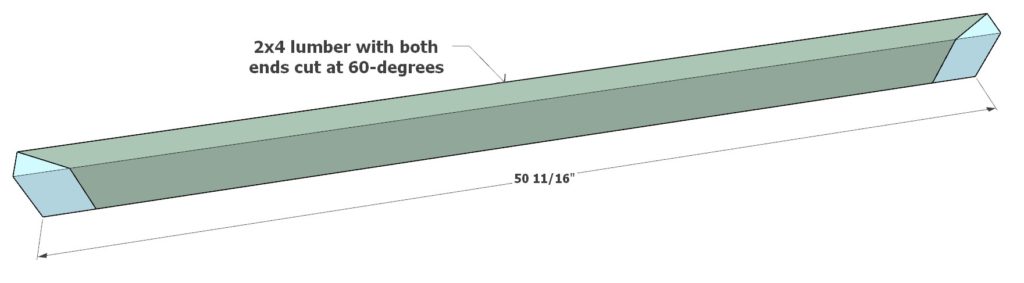

- Central Support Beam (Dark Teal): Cut one piece of 2×4 lumber to 50-11/16 inches with both ends at 60-degrees.

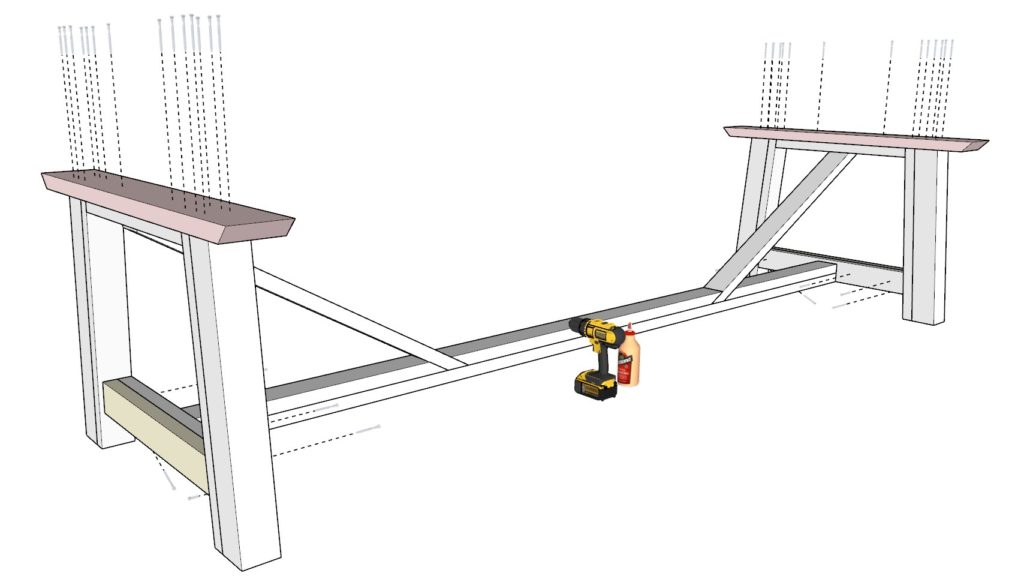

Assembling the Base Frame:

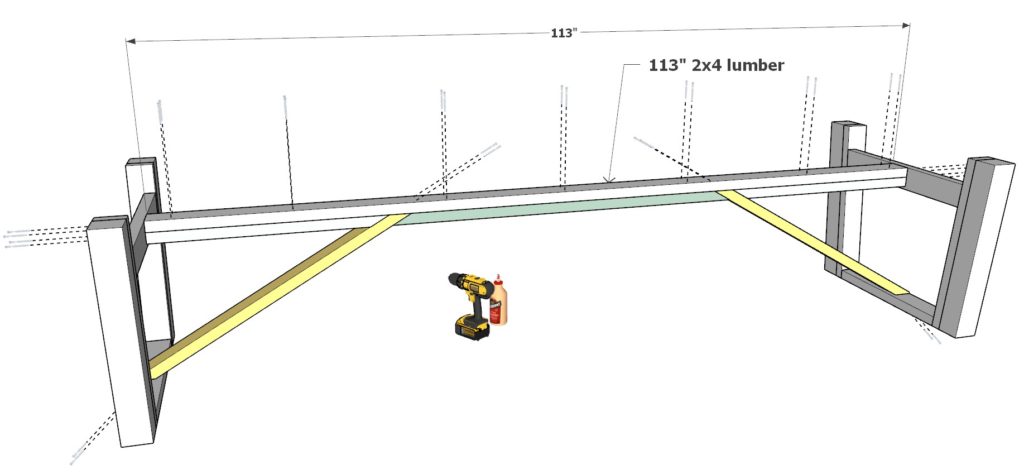

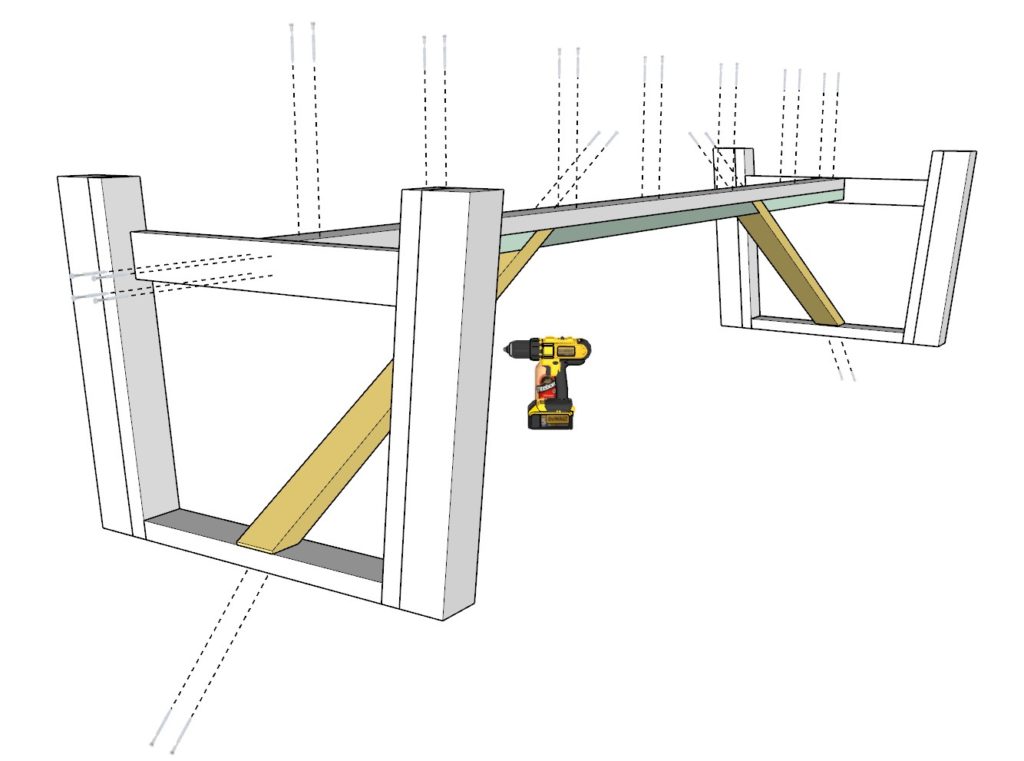

- Connect the A-Frames: Position the bright yellow long cross beams, teal short cross beams, and the dark teal central support beam to join the A-frame leg pieces together.

- Attach the Horizontal Beam: Incorporate the 113-inch 2×4 (uncut and in white) horizontally across the structure.

- Securing the Structure: Use 3.5-inch screws for most connections, switching to 2.5-inch screws in areas where longer screws might poke through.

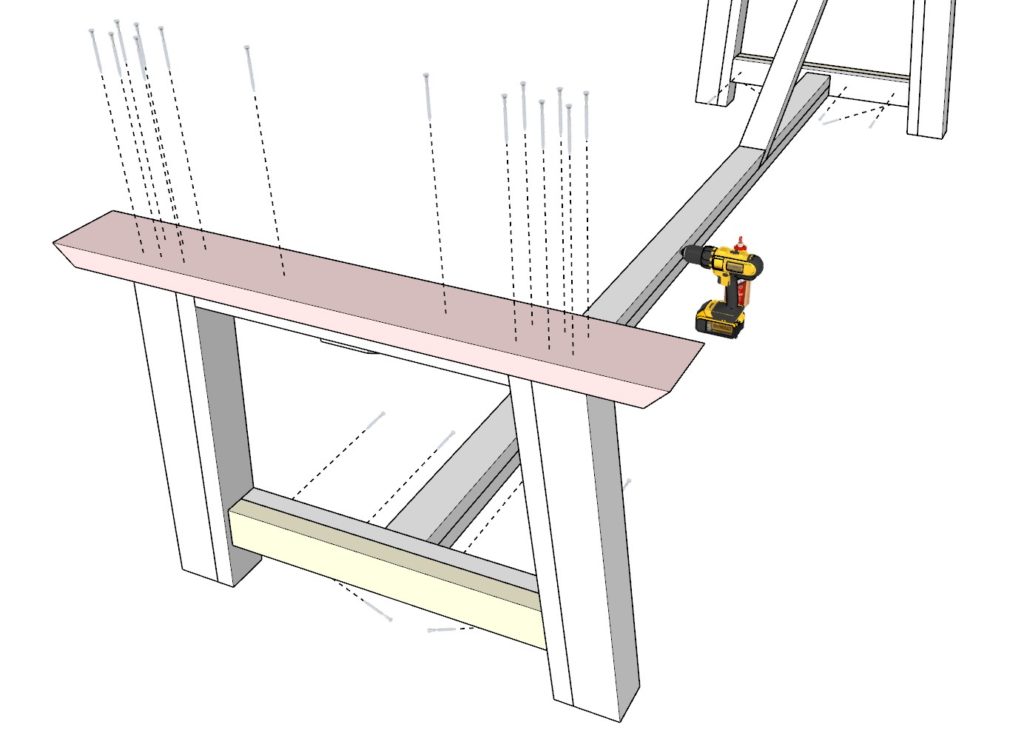

Finalizing the Frame:

- Add Pink and Pastel Yellow Pieces: From Step 1, attach the pink 2x6s and the pastel yellow 2x4s to the assembly with wood glue and a combination of 2.5-inch and 3.5-inch screws, depending on placement and depth.

Tips for a Clean Assembly:

- Screw Placement: Follow the diagram closely for optimal screw placement, especially if you’re opting not to use dowels or wood putty, as this will help to conceal the screws for a more polished look.

Step 4: Preparing and Finishing the Wood

Preparing for Staining and Painting:

- Sand the wood thoroughly, starting with a coarse-grit sandpaper and progressing to a fine-grit paper for a smooth finish.

- Remove all dust with a tack cloth or a damp rag to ensure a clean surface.

Using Wood Conditioners and Pre-Stains:

- Pros: They can help achieve a more even stain application, especially on woods like pine that tend to absorb stains unevenly.

- Cons: Additional step and cost; may not be necessary for all wood types or desired finishes.

Distressing Wood Techniques:

- Physical Techniques: Use tools like hammers, chains, and screws to create dents and scratches for an aged look.

- Finish Techniques: Apply layers of paint, then sand in places to reveal the wood or underlying paint colors.

- Pros and Cons: Physical distressing offers authenticity; however, it can weaken the wood if overdone. Finish techniques can be less damaging but may look less natural.

Staining Wood:

- Apply stain with a brush or rag, working along the wood grain.

- Wipe off excess stain with a clean rag for an even finish.

- Apply multiple coats until the desired color is achieved, allowing adequate drying time between coats.

Painting Wood:

- Apply a primer coat and let it dry completely to ensure paint adhesion.

- Use a high-quality paintbrush or roller to apply paint in thin, even coats.

- Sand lightly between coats for a smooth, professional finish.

Maintaining Your Table Base:

- For indoor use, dust regularly and clean spills quickly with a dry cloth.

- Reapply a protective finish, such as polyurethane, every few years or as needed.

- For outdoor use, consider a UV-protective sealant, and cover or store the table during harsh weather.